The content of the site is protected by copyright as intellectual property. Without the written consent of romehome.ro, copying (in any form) of any part of the website (design, text, images, etc.) is not accepted.

„God is in the details” – Ludwig Mies van der Rohe

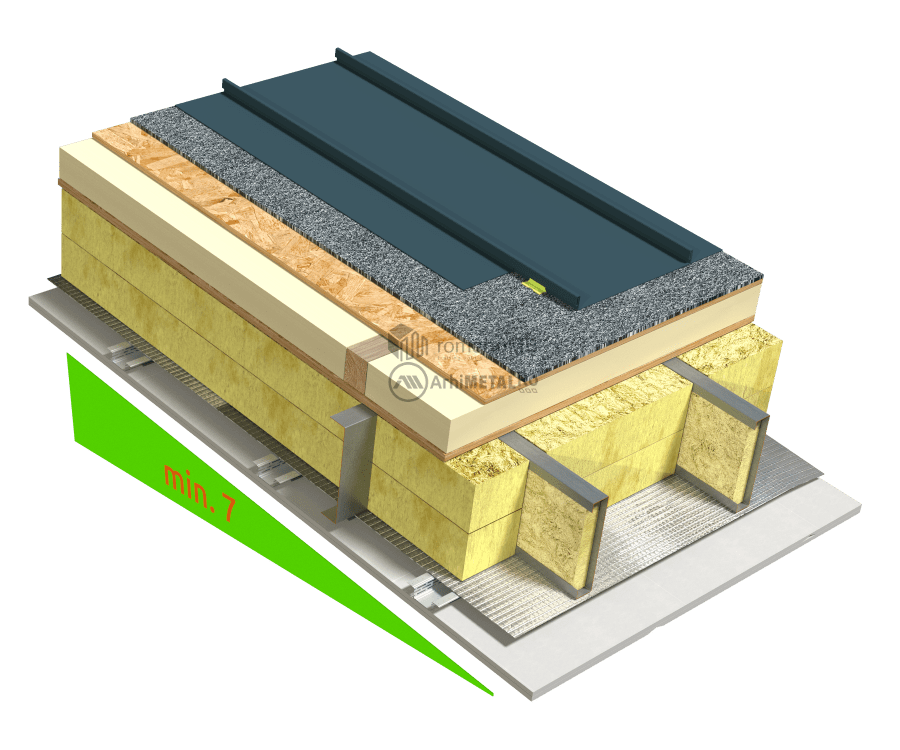

Terraces with low-slope roofs

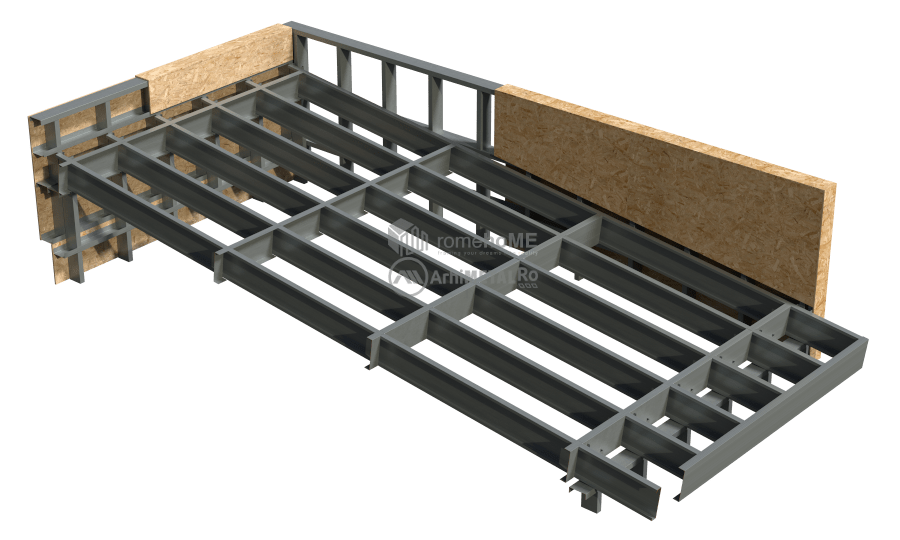

The frame structure can provide efficient solutions for both non-walkable and walkable terraces.

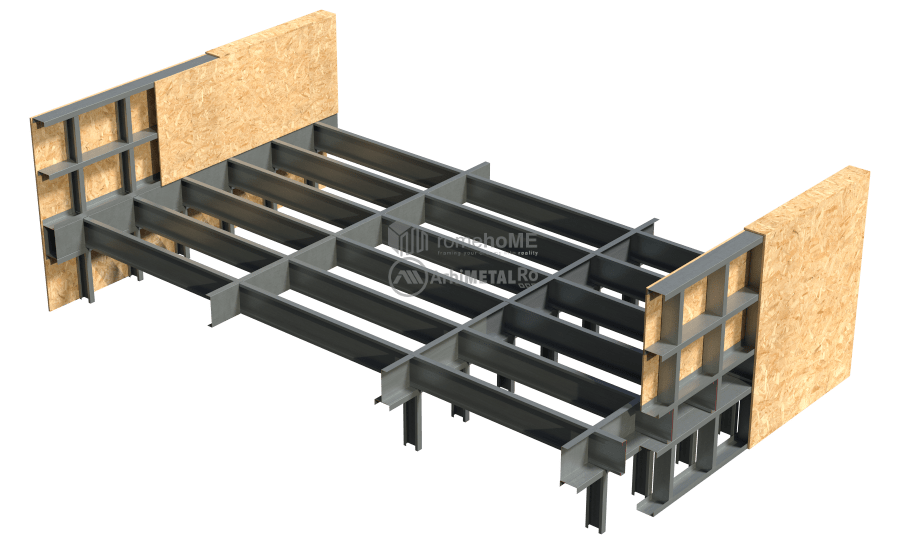

FRAME STRUCTURE

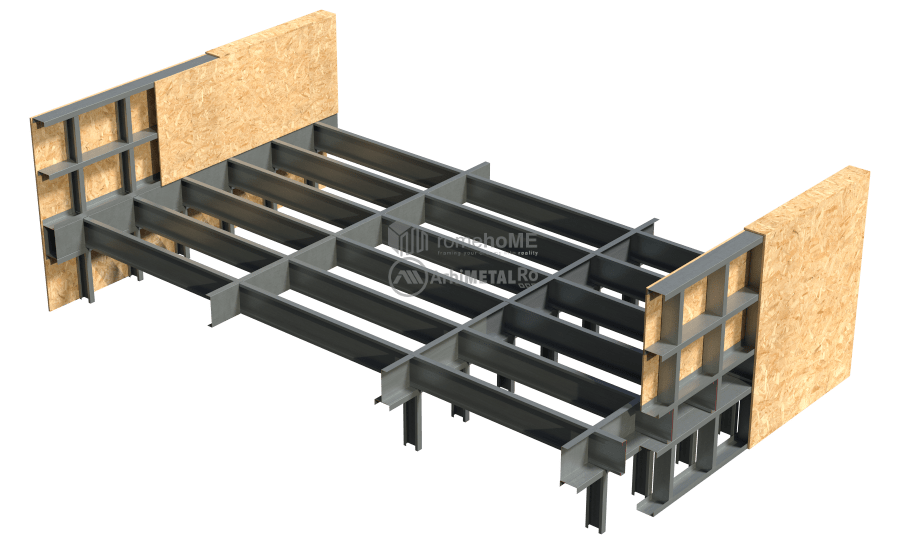

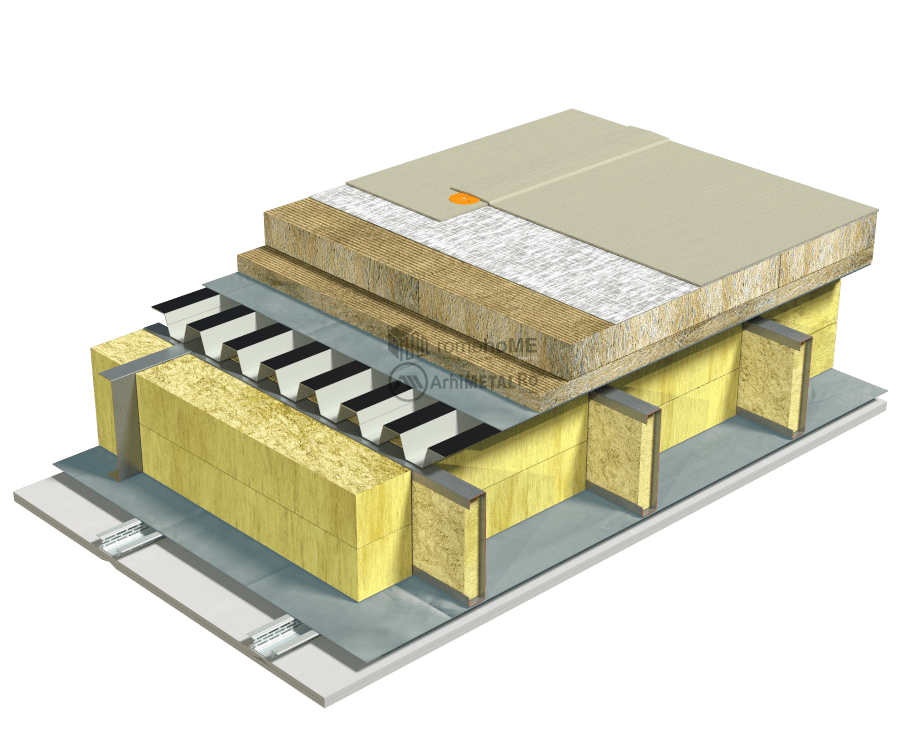

From a structural point of view, terraces are very similar to intermediate floors, and depending on the openings and loads, C/U200 or C/U300 profiles with single or double arrangement (back-to-back) can be used.

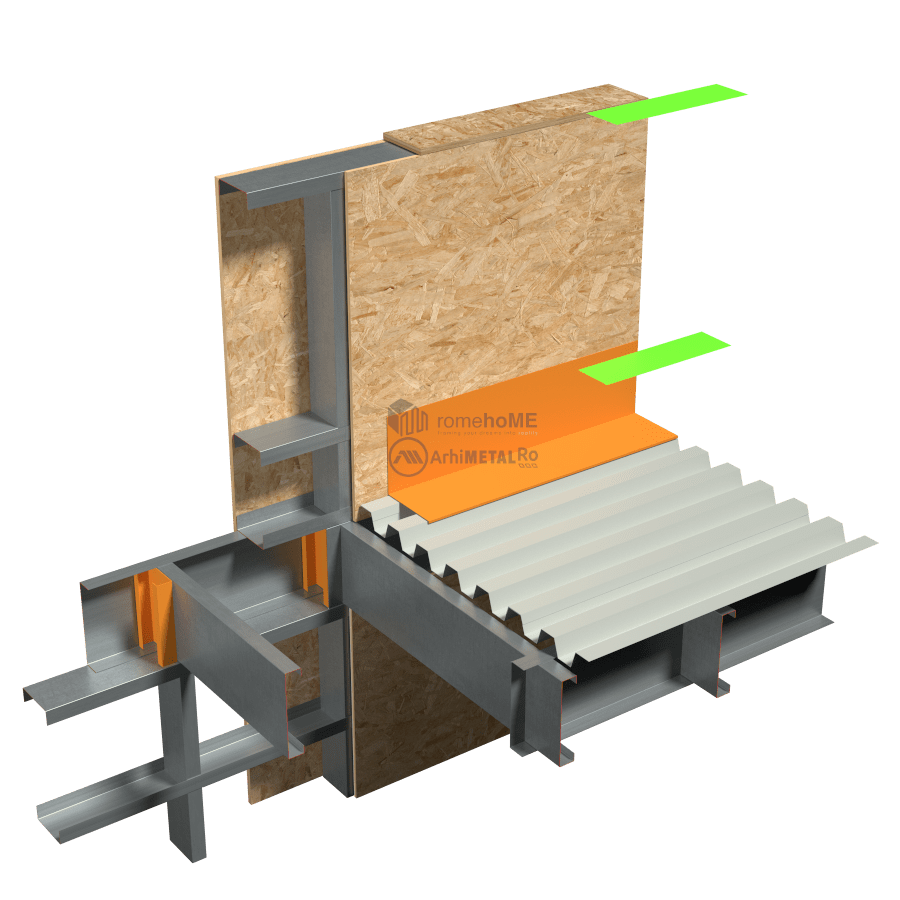

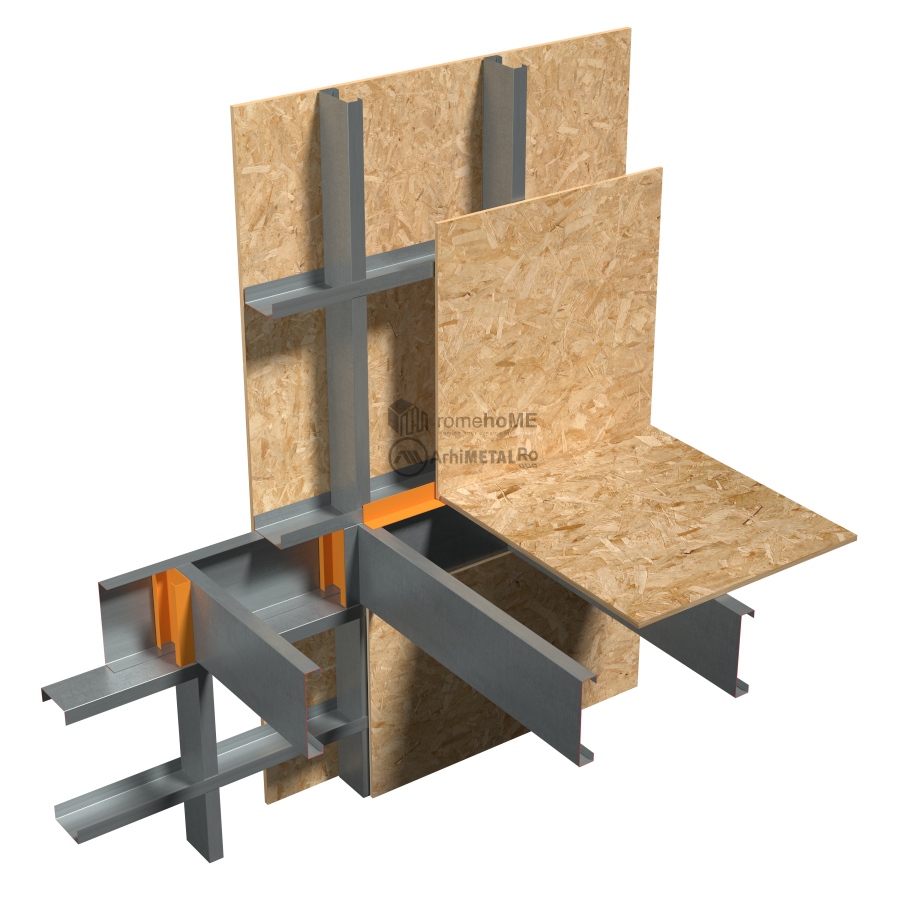

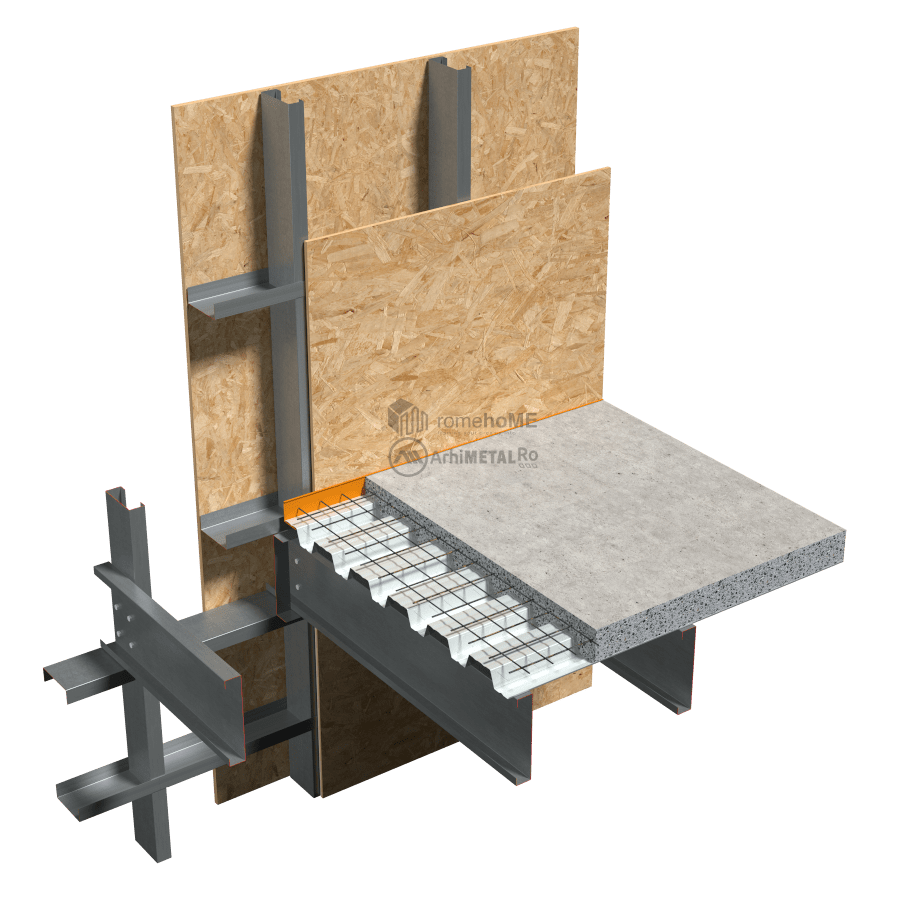

There are two ways to arrange the terrace floor within the frame structure:

• with interrupted studs;

• with continuous wall studs;

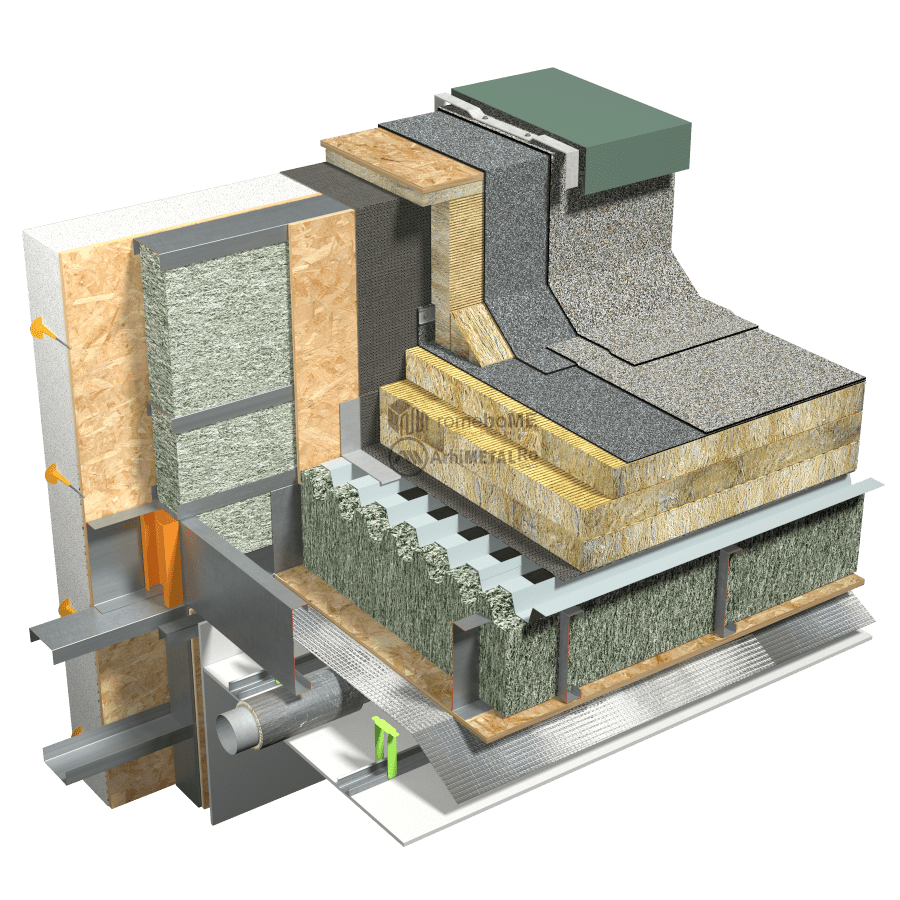

ATTIC ARRANGEMENT

Attics can be installed in three ways, and there are height limitations depending on the installation method:

- by simply resting on the terrace floor – maximum height 0.9 m;

- by applying it on the facade walls – maximum height approximately 2/3 above the floor and 1/3 on the facade;

- continuation of the facade profiles – maximum height 1.5 m;

Their shape can fulfill functional, structural, or aesthetic requirements, without being limited by the frame structure (LSF).

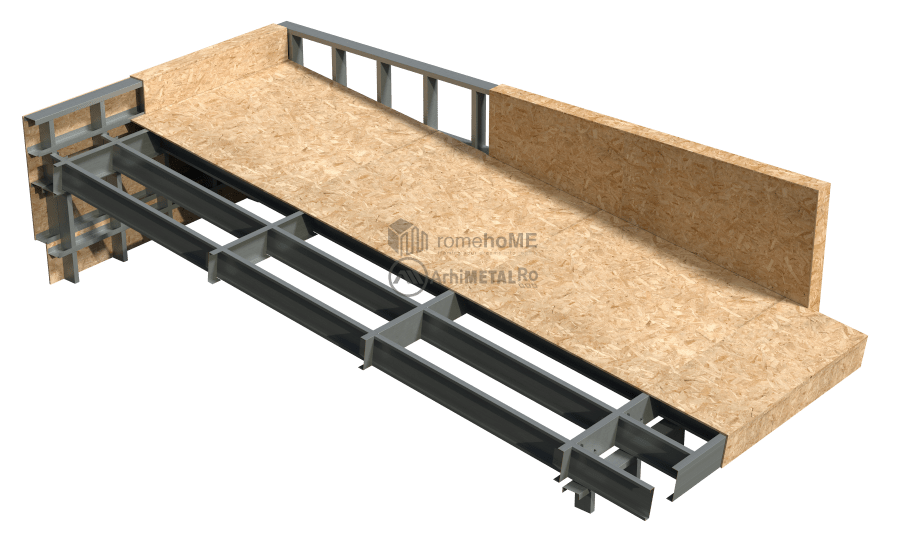

TERRACE STRUCTURE CLADDING

Options for cladding the upper part of the terrace floor:

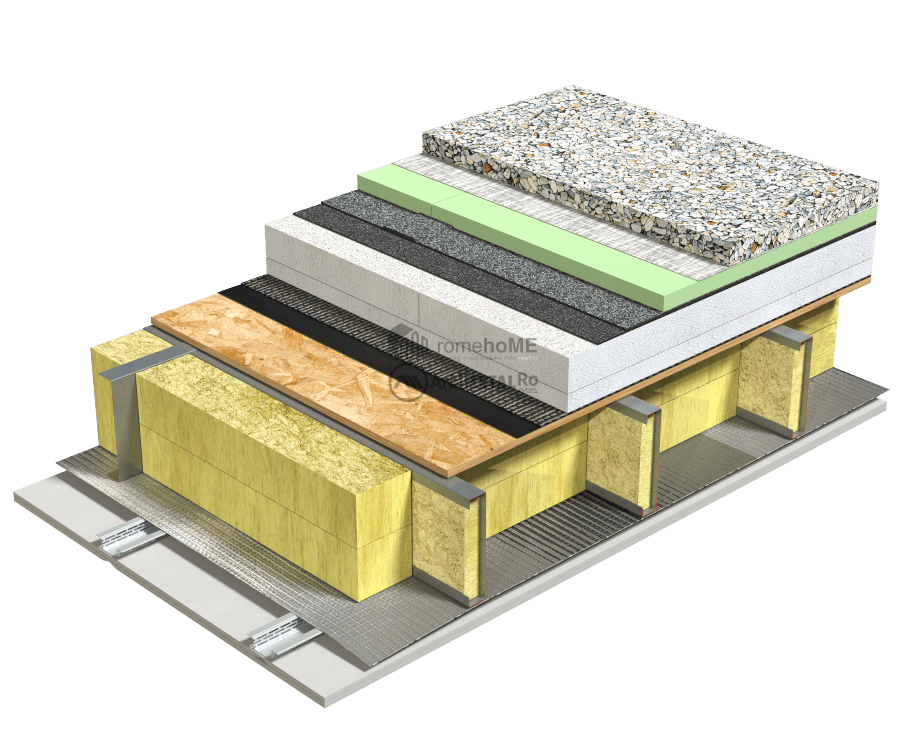

• cladding with OSB 3 – 22 mm thickness – in one or even two staggered layers, or replacing the second layer of OSB with a cement-based board, depending on the specific requirements of the flooring;

• using a lightweight concrete floor poured in a permanent formwork made of corrugated sheet metal;

• corrugated sheet metal as a support for terrace insulation (only for non-walkable terraces).

Depending on the insulation used – mineral wool, cellulose fibers, wood fibers – at the lower part of the frame structure, either only profiles are used to fix the gypsum board, or it can be closed with a minimum 15 mm thick OSB 3 board, which serves as a support structure for the gypsum boards.

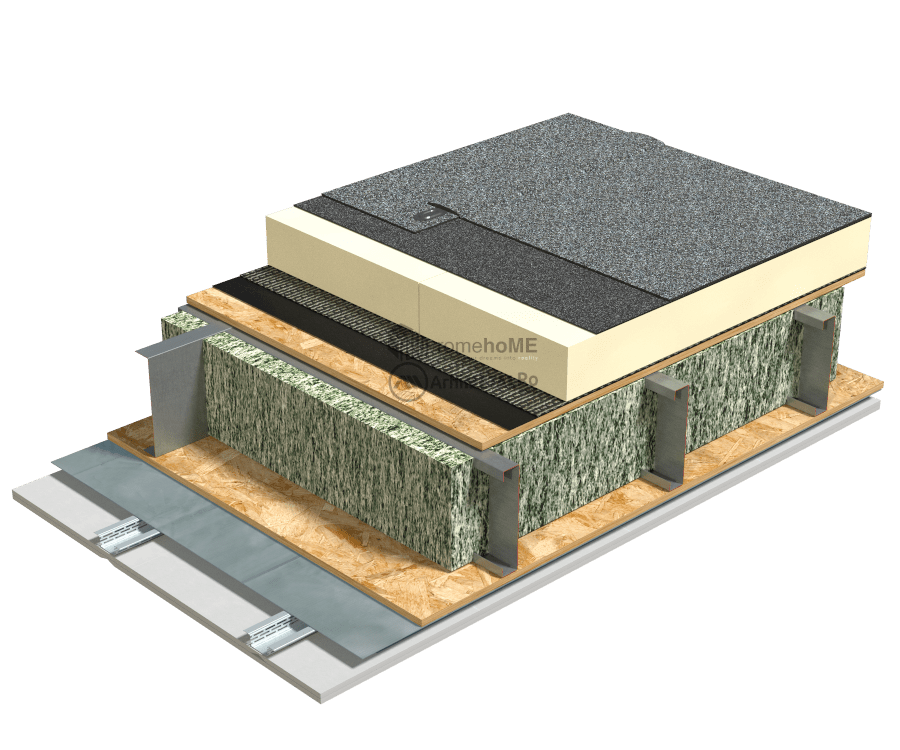

INSULATION AND THERMAL INSULATION

Within the frame structure

The same materials and technologies used for intermediate floors are applicable. Depending on specific requirements or needs, one of the specified options can be chosen.

THERMAL INSULATION ABOVE THE FLOOR

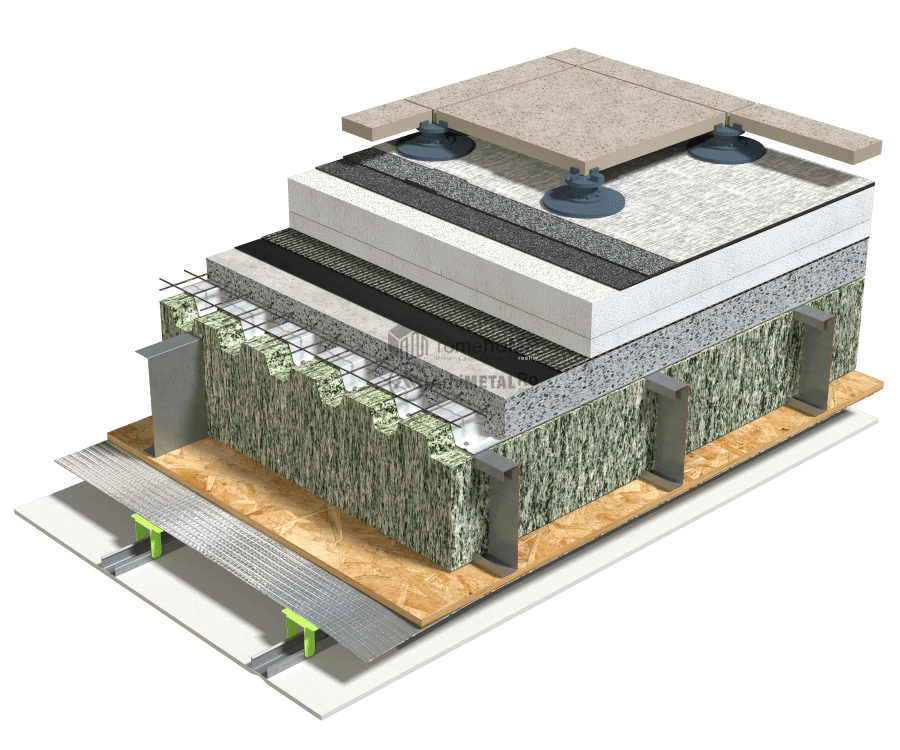

For terrace thermal insulation, only rigid or semi-rigid thermal insulation materials can be used, depending on the type of terrace and the type of waterproofing.

The slope of the terrace – up to 3 degrees – can be created using the thermal insulation material.

The options for thermal insulation include materials such as:

• bitumen-coated expanded polystyrene EPS 200;

• rigid basalt wool;

• rigid polyurethane foam (PIR) panels;

The minimum thickness of the thermal insulation material is recommended to be at least 20 cm, depending on the thermal insulation of the terrace floor

Remember that the correct sizing of thermal insulation is subject to thermal engineering calculations!

WATERPROOFING

For terraces, we usually recommend bituminous waterproofing membranes with polyester reinforcement, providing flexibility at -20 degrees Celsius and a thickness of 5 mm.

Another high-performance option for terrace waterproofing is PVC membranes.

SEALING

Regardless of the type of terrace detail, it is mandatory to install a vapor barrier film at the underside of the floor to prevent vapor transfer through the floor structure to the upper layers.

As a general rule, it is advisable to avoid piercing this barrier with technical routes, installations, or chimney flues, etc.

All these penetrations must be taken into account from the modeling phase.

ATTENTION!!! Sealing and thermal insulation without thermal bridges are two of the most important factors in achieving a construction with a healthy indoor microclimate and energy efficiency.

TERRACE FINISHING

For walkable terraces, floating floors on pedestals or decking made of wood or composites are recommended.

For green terraces, only the extensive option with low-height plants and covering approximately 25% of the terrace area is recommended.

Water drainage should be directed towards gutters or hidden downpipes, and only in special cases should drain outlets pass through the interior of the structure.

In all drainage options, it is recommended to include anti-freezing systems to prevent water from freezing and causing blockages.

For the installation of skylights or domes, there are integration options with the terrace details, with the consideration that this should be taken into account during the design phase.

TECHNICAL OPENINGS AND INSTALLATIONS

As a general rule, we recommend avoiding technical penetrations through the terrace floor.

In case ventilation/exhaust/air conditioning equipment will be installed, they should be planned during the design phase to provide the necessary supports for their installation without compromising the terrace waterproofing.

Waterproofing should be doubled in circulation and support areas.

GYPSUM BOARD CLADDING ON THE UNDERSIDE OF THE FLOOR

It is the simplest and most efficient method to enclose the undersides of the floors.

Gypsum boards can be either attached to the frame structure or fixed to the OSB board on its underside.

Depending on the project requirements, all recommended installation details by gypsum board system manufacturers can be used.

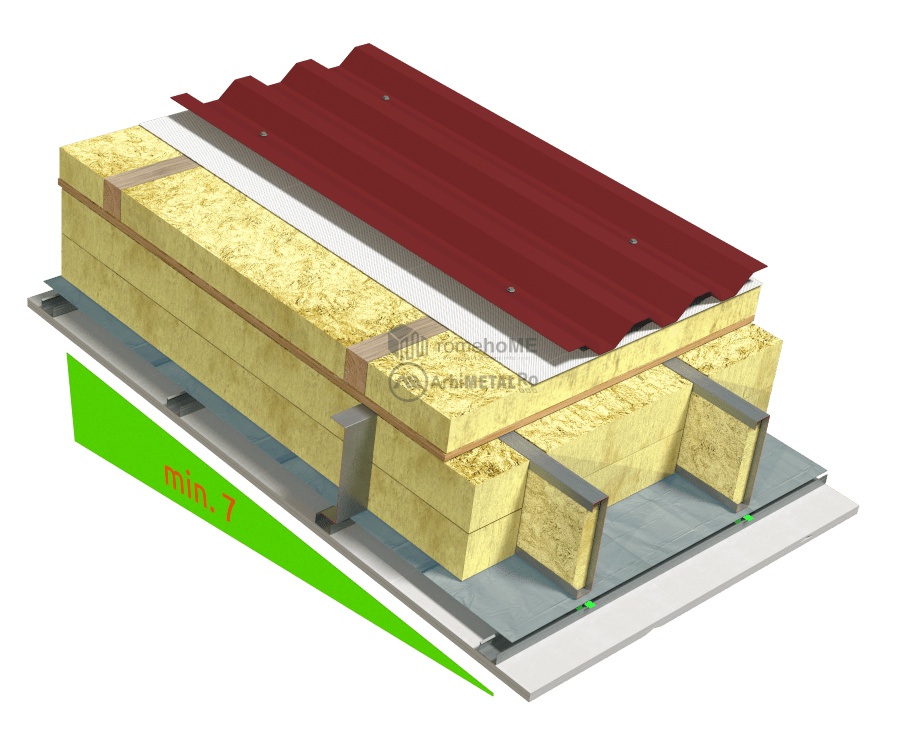

DETAILS OF LOW-SLOPE ROOFS

Although they fall under the terrace category, low-slope roofs, with slopes between 5 and 15 degrees, provide an efficient solution for enclosing the upper part of the frame structure, combining the advantages of terraces and sloped roofs.

FRAME STRUCTURE

C/U 160, 200, 300 profiles are used depending on the spans between supports and the roof area.

The roof can be designed with attics on three sides, similar to terraces, or with a projecting roof structure, depending on the architectural design.

THERMAL PROTECTION

Thermal protection is achieved by installing an insulation layer with a thickness of up to 12 cm to prevent thermal bridging through the roof structure.” ”Depending on the type of roofing, rigid or semi-rigid thermal insulation materials such as mineral wool, PIR, or expanded polystyrene (EPS) can be used.

ROOFING MATERIALS

For low-slope roofs, it is recommended to use roofing materials that can be installed in a single strip or, according to the manufacturer’s installation guidelines, on slopes as low as 15 degrees.

Options include double-folded or click-lock metal sheets, corrugated sheets, bituminous shingles, or even prefabricated panels.

As a general rule, low-slope roofs should have a single slope without valleys!