The content of the site is protected by copyright as intellectual property. Without the written consent of romehome.ro, copying (in any form) of any part of the website (design, text, images, etc.) is not accepted.

„A house is a machine for living in” – LeCorbusier

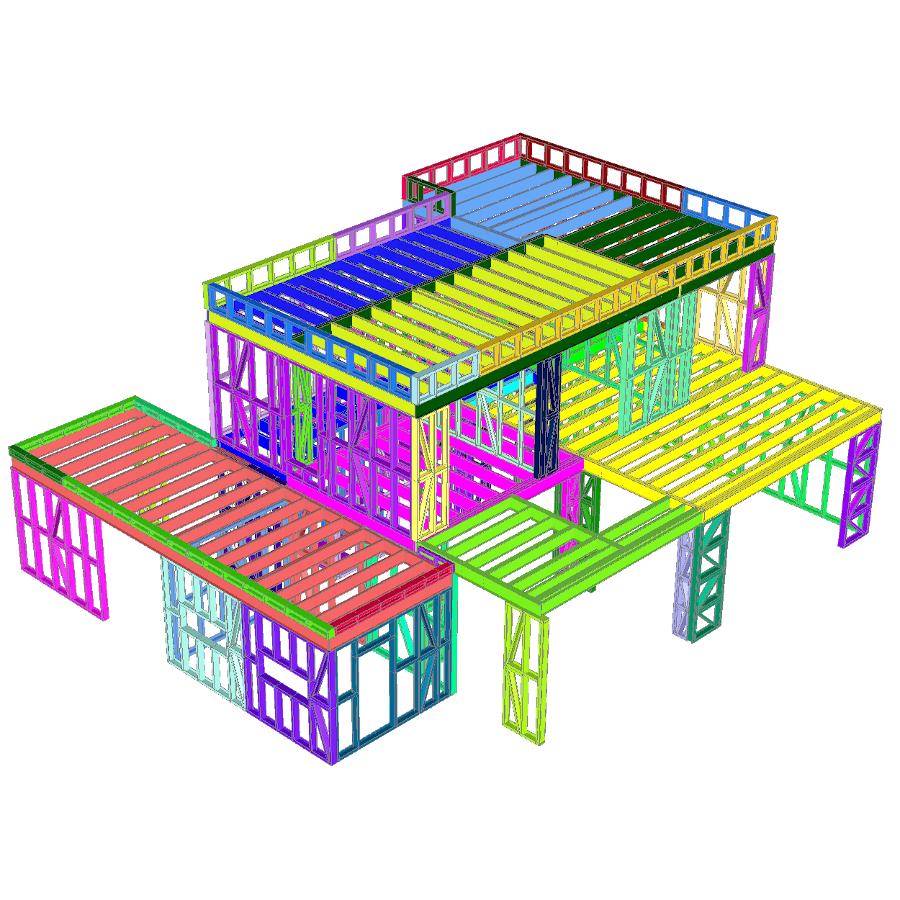

Installation of the frame structure

The frame structure from romehoME is obtained through an integrated process of architectural design, structural engineering, and installation, as well as 3D modeling of structural elements using dedicated software. This, along with the installation carried out according to our requirements by a specialized team, results in a high-performance and unified structure with exceptional strength and stability against all types of loads, especially earthquakes.

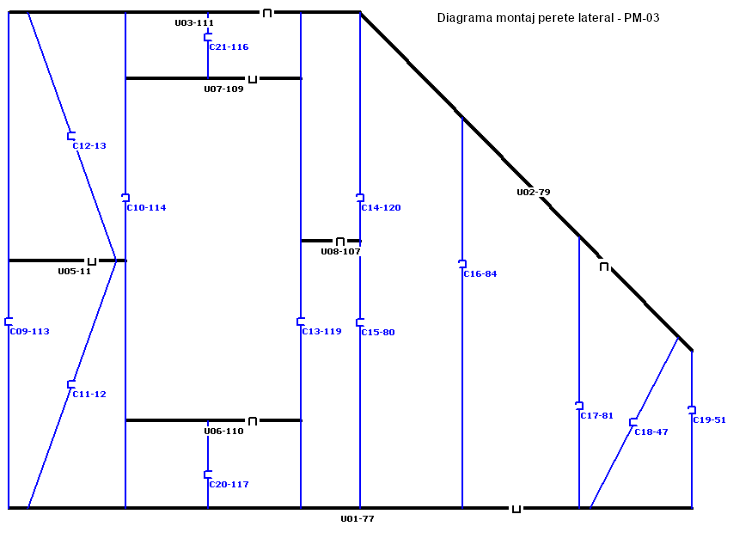

ASSEMBLY DIAGRAM

The assembly of the romehoME frame structure is done strictly according to the assembly diagram provided by the factory, which specifies the type and quantity of profiles for each structural module, without the need for on-site adaptations, adjustments, or other ‘improvements’.

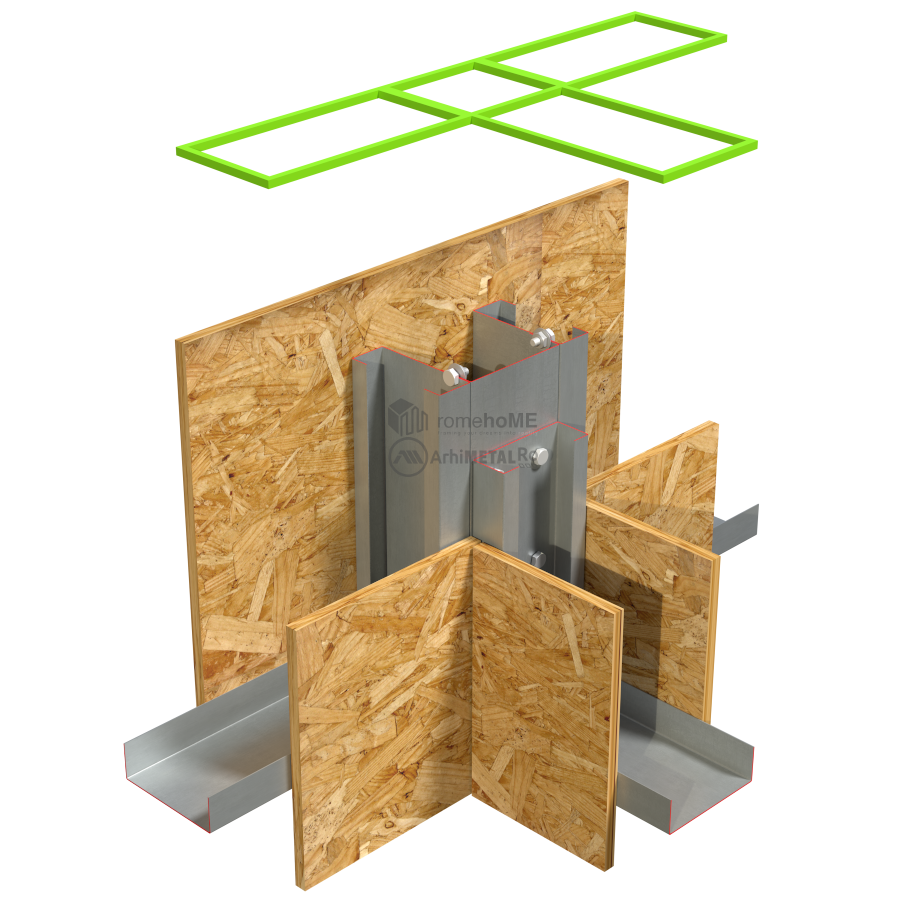

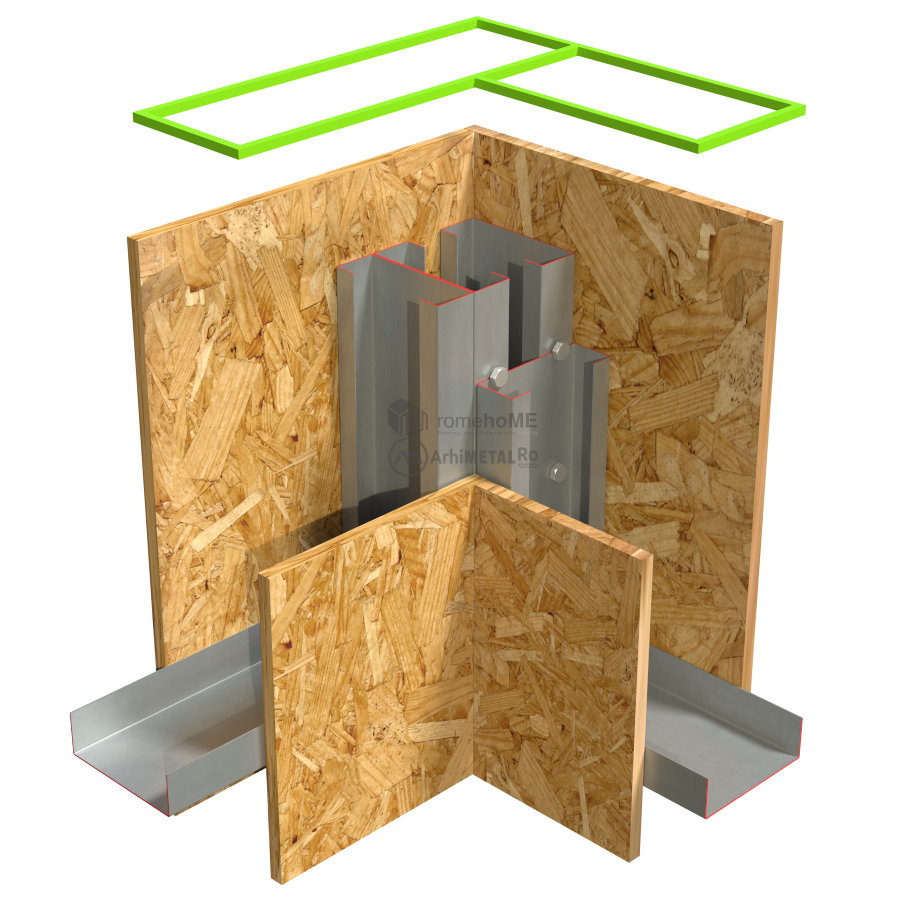

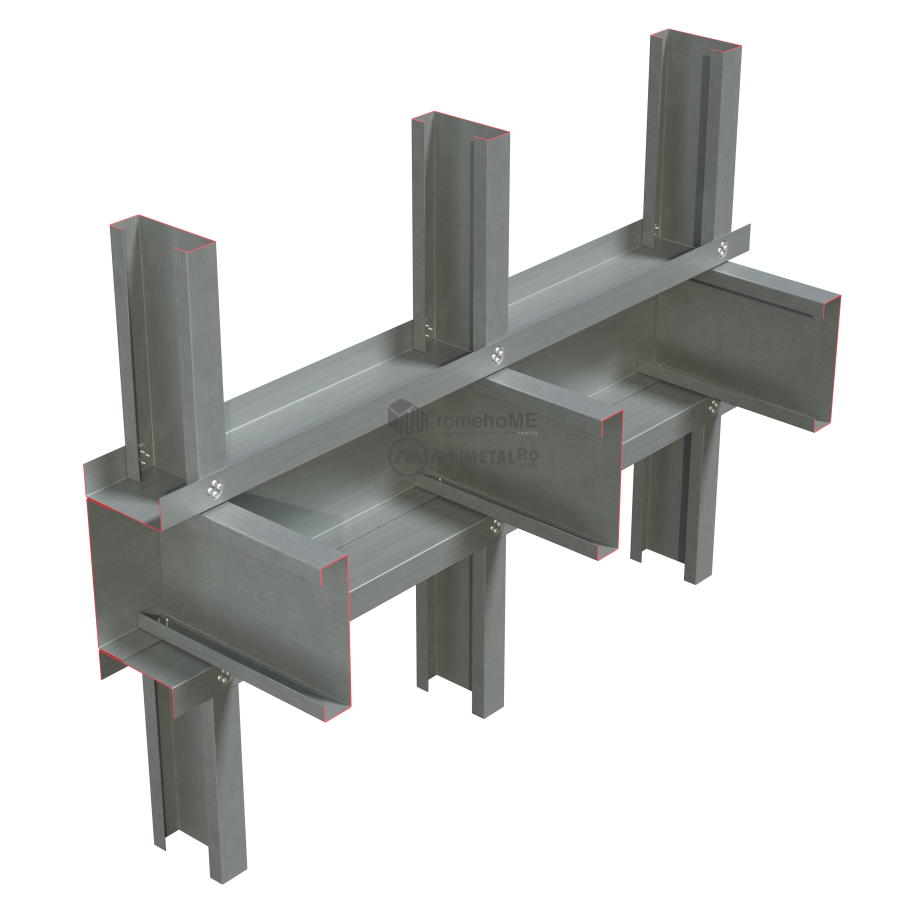

PROFILES ASSEMBLY

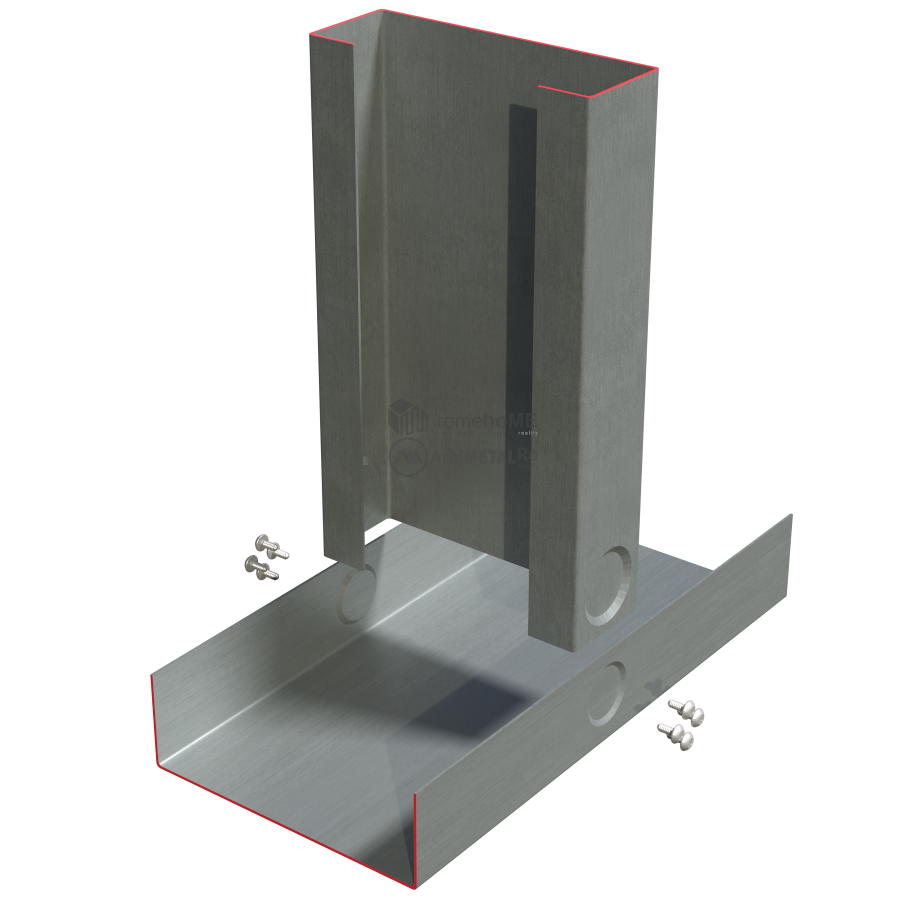

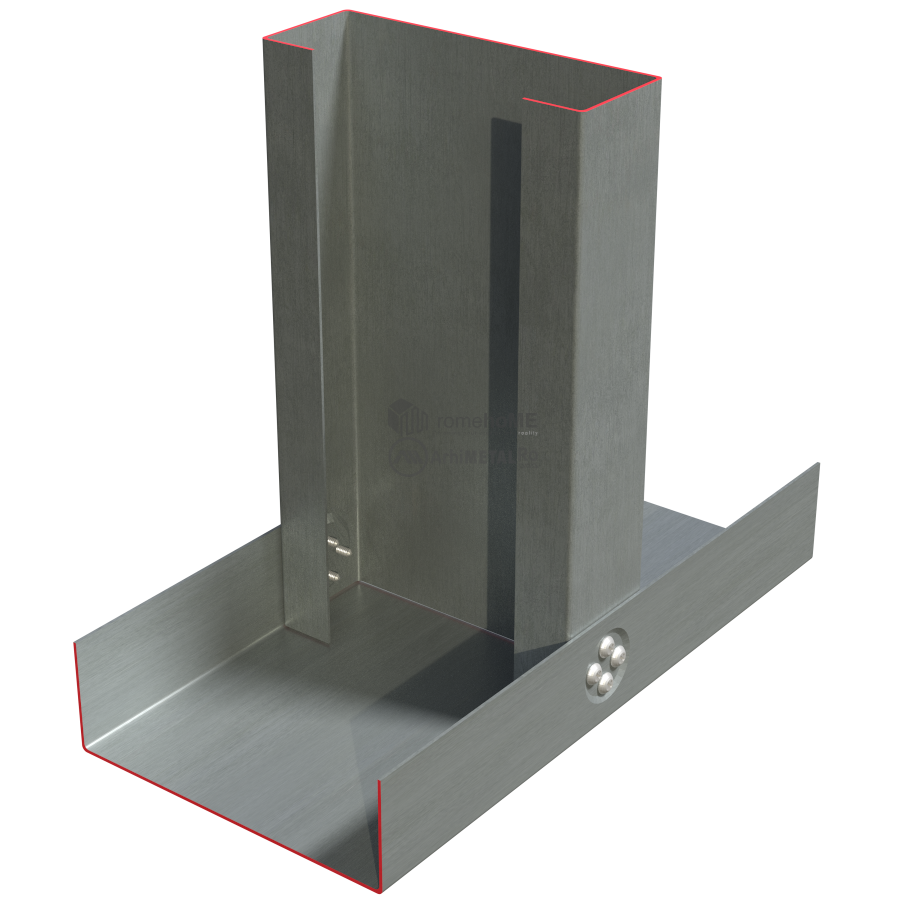

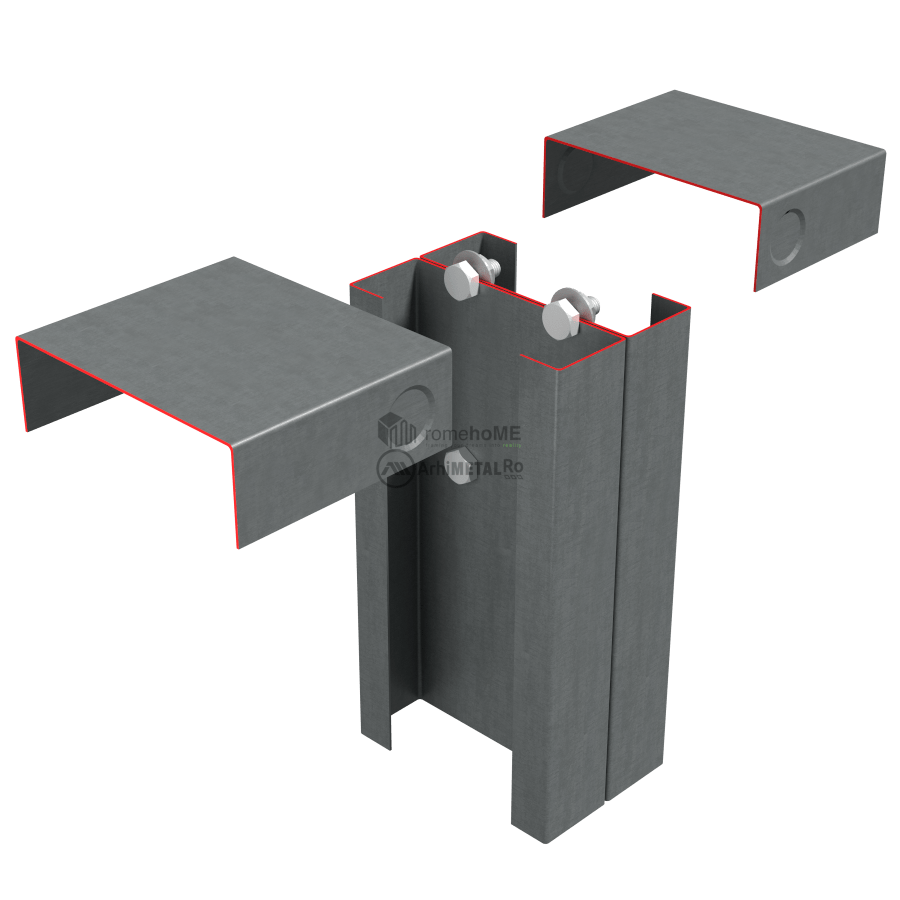

During the assembly, the C profiles are connected to the U profiles only at the specifically embossed locations in the manufacturing process.

The outer dimension of the C profile matches the inner dimension of the U profile.

The embossing of the nodes allows for easy installation of the profiles and hides the screw heads, ensuring that the cladding of the structure does not rely on them for support. The nodes are fixed with 8 screws per node (4 on each side), contributing to the rigidity of the romehoME frame structure. romehoME is the only company in Romania capable of achieving this type of fastening!

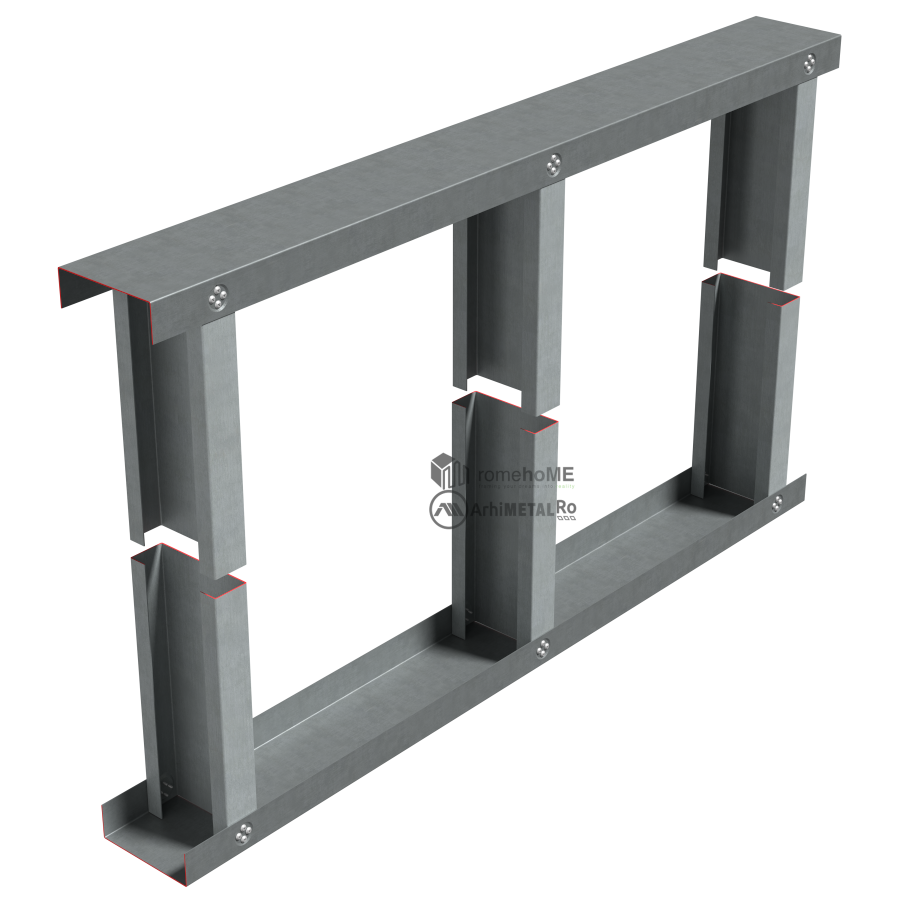

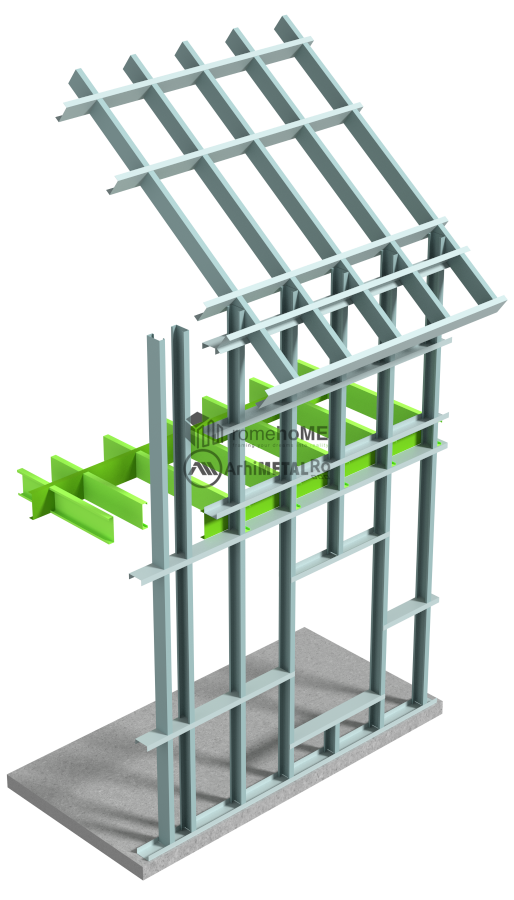

STRUCTURAL MODULES

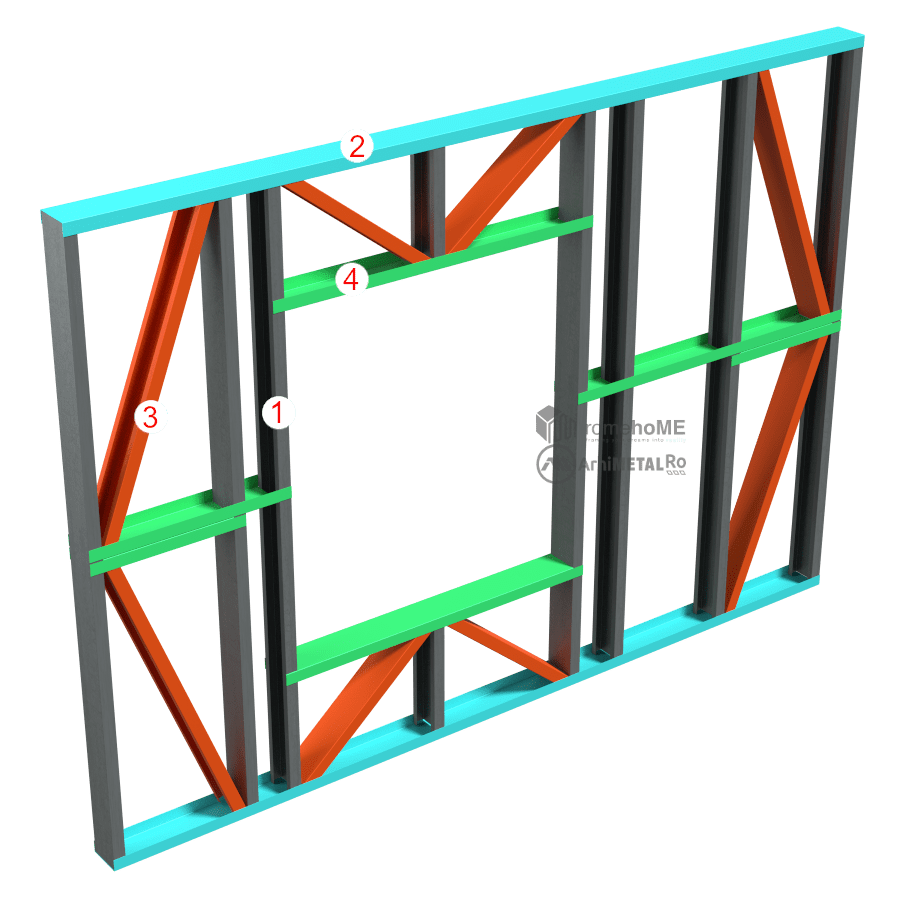

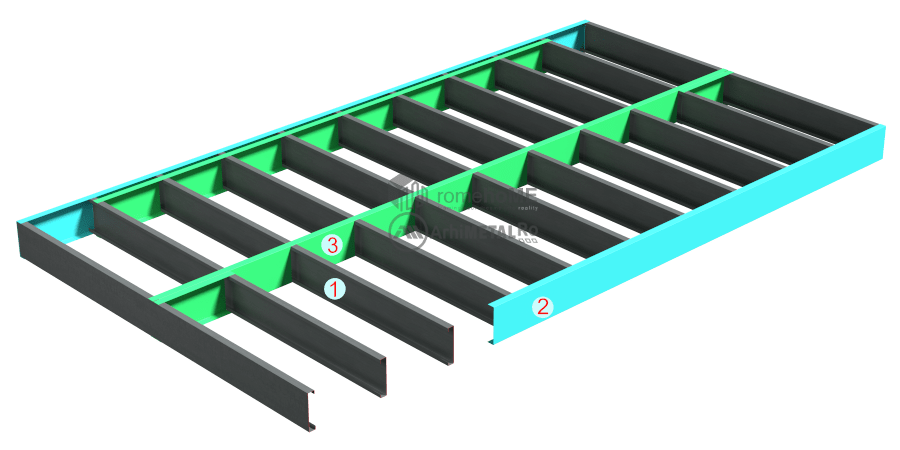

Assembly of C and U profiles allows for the creation of structural modules:

• vertical modules – for facade walls, interior walls, attics, etc;

• horizontal modules – for floors, terraces, balconies, etc;

• inclined modules – for roofs, stairs, etc;

• trusses, lattice beams – in various configuration options;

As a general rule, the creation of modules for load-bearing elements, walls, floors, terraces, roofs, etc., takes into account the safe transportation and handling of profiles and modules with minimal personnel, both in the factory and on the construction site.

Depending on transportation options and site access, modules can be assembled either in the factory or directly on the construction site.

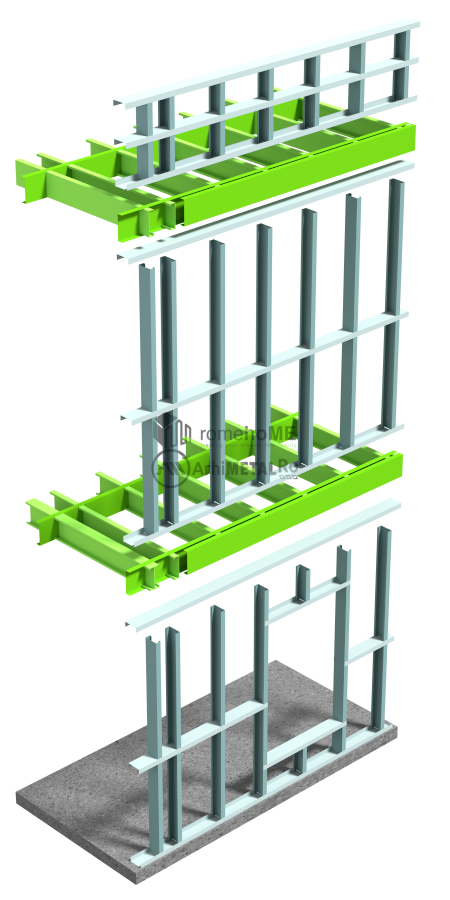

ASSEMBLY OF MODULES

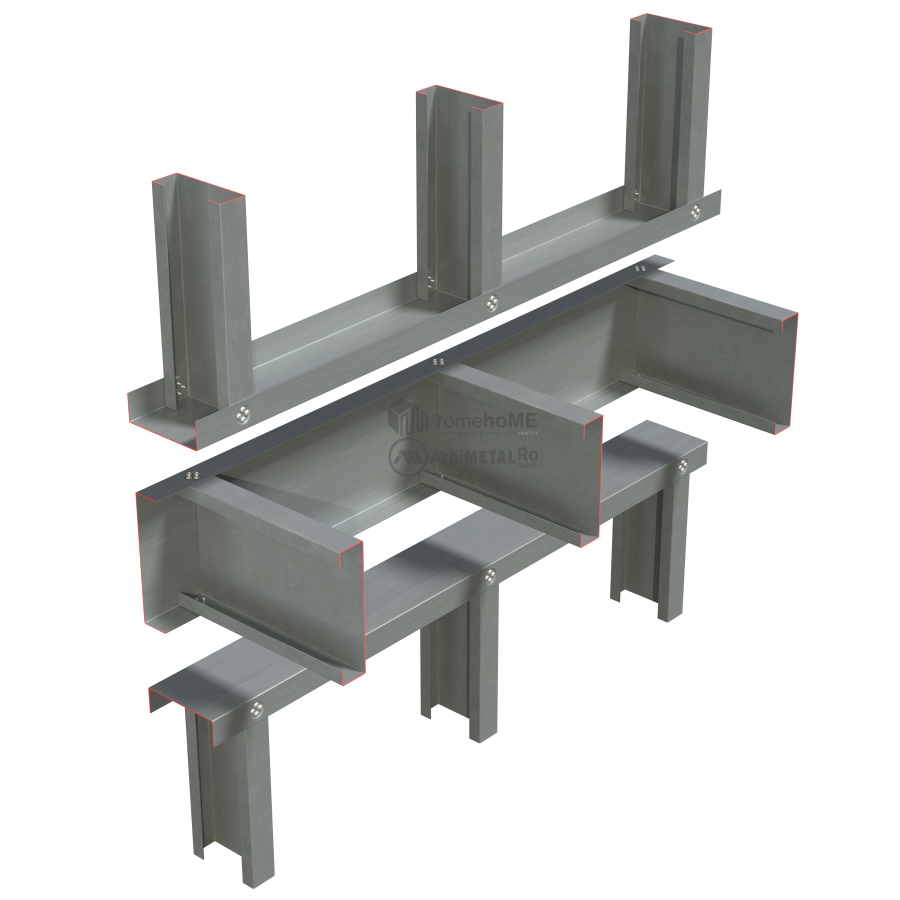

The number of fixing points between modules is calculated by the structural engineer during the 3D modeling of the structure, and the perforations for installations are formed during the production of the profiles.

Connections between modules are made on-site using metric screws with washers and nuts, in the pre-drilled holes. Galvanized steel screws with a strength grade of 8.8, size M12x22/35, are used.

On-site, the placement of additional holes or the widening of existing ones is not allowed.

This can give you a comprehensive view of the precision with which the components of the frame structure are designed and produced at the romehoME factory.

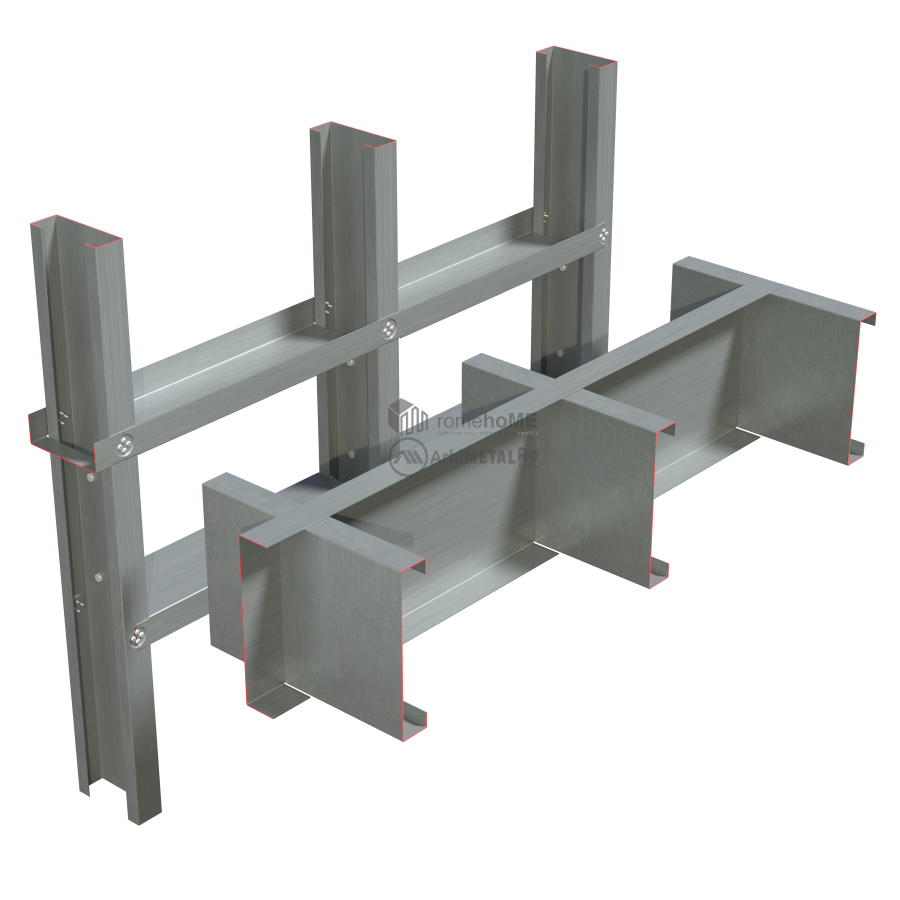

CONSTRUCTIONS WITH SEPARATED WALLS AND FLOORS

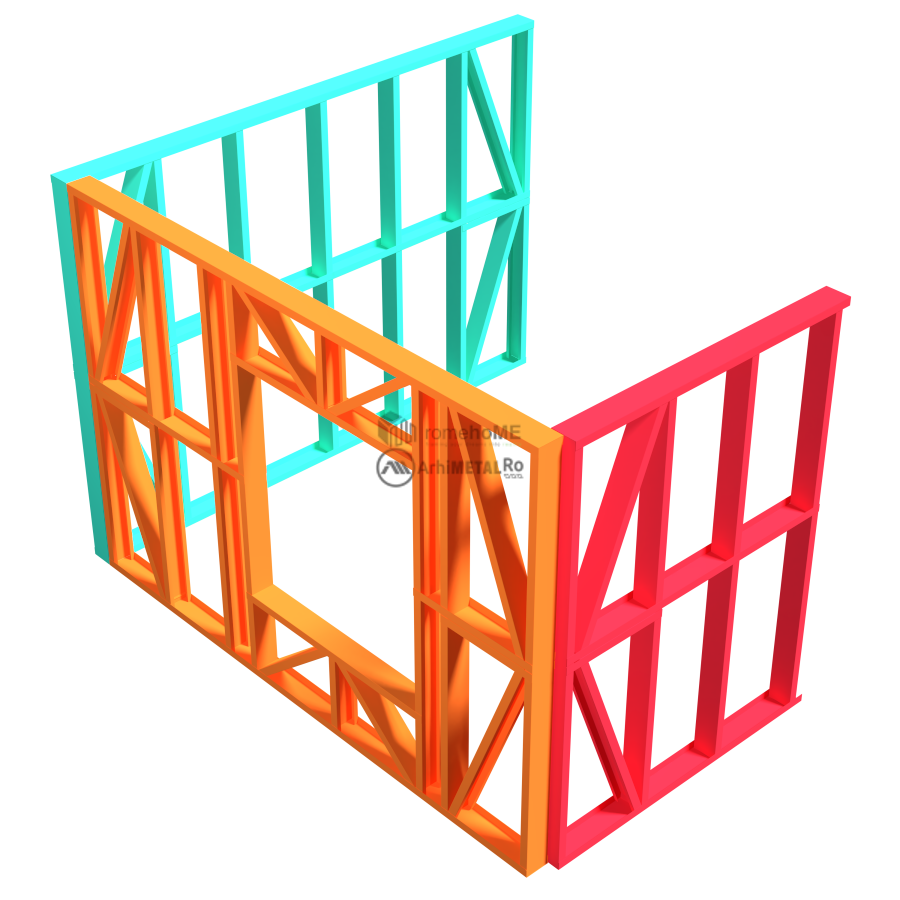

There are two assembly systems for the structural modules:

Assembly system where both the ground floor walls and the upper floor/attic walls are attached to the intermediate floor, which is derived from conventional construction systems with floors and walls.

This assembly method is the most well-known and widely used because it allows for easy assembly of the structure, as well as convenient transportation and handling of the profiles and modules.

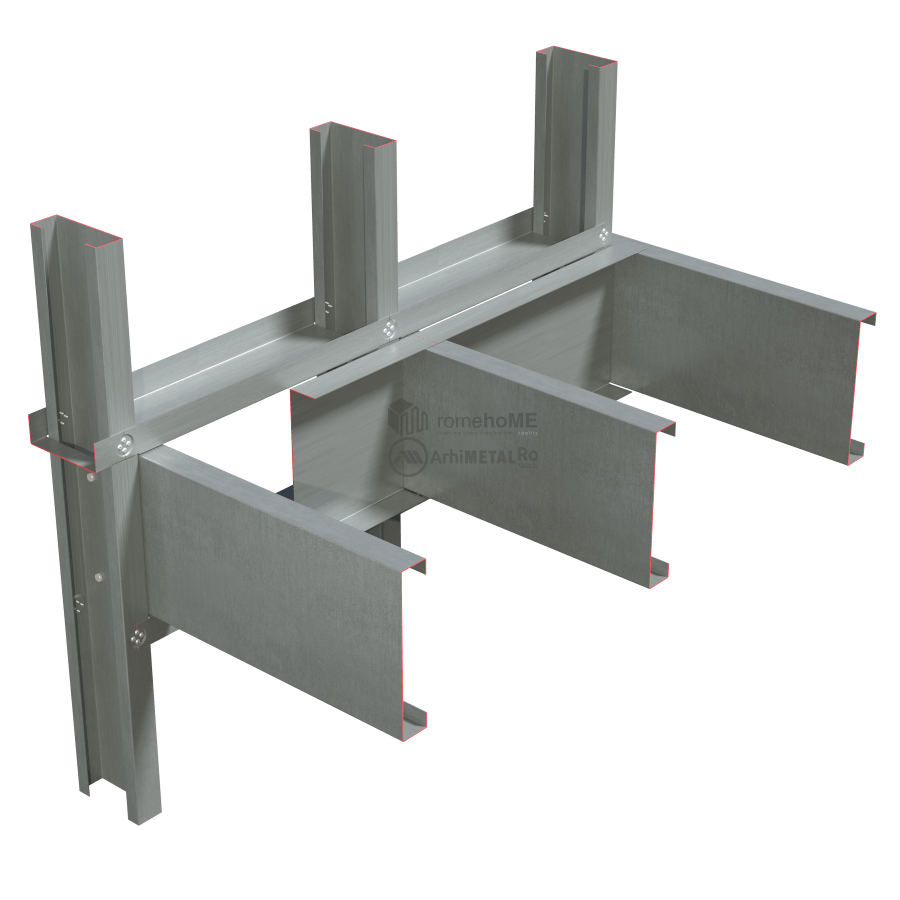

CONSTRUCTIONS WITH CONTINUOUS WALLS

Assembly system where the floor is attached to the wall profiles that remain continuous throughout the height. This assembly method is mainly used in modular constructions or constructions with a single floor or a ground floor and an attic. The advantage of this method is that it simplifies the connection details, but it can make the handling and assembly of modules more difficult on the construction site.

IMPORTANT!

The sizing and arrangement of the profiles and modules within the construction are subject to structural calculations for each project, and there are several factors that influence this:

• spans between supports as well as openings for windows, doors, stairs, etc;

• loads and stresses according to current regulations;

• limitations related to transportation and/or handling.;

• thermal insulation, acoustic properties, elasticity, vibrations;

It should be noted that a light steel frame structure is highly versatile in terms of the arrangement and sizing of both profiles and modules, and it can have multiple solutions for the same structural detail, depending on the requirements that the element must meet.

romehoME sells calculated and verified structures made from thin-walled profiles of galvanized steel sheet, not just profiles!