The content of the site is protected by copyright as intellectual property. Without the written consent of romehome.ro, copying (in any form) of any part of the website (design, text, images, etc.) is not accepted.

„A house is a machine for living in” – LeCorbusier

How does the frame structure work

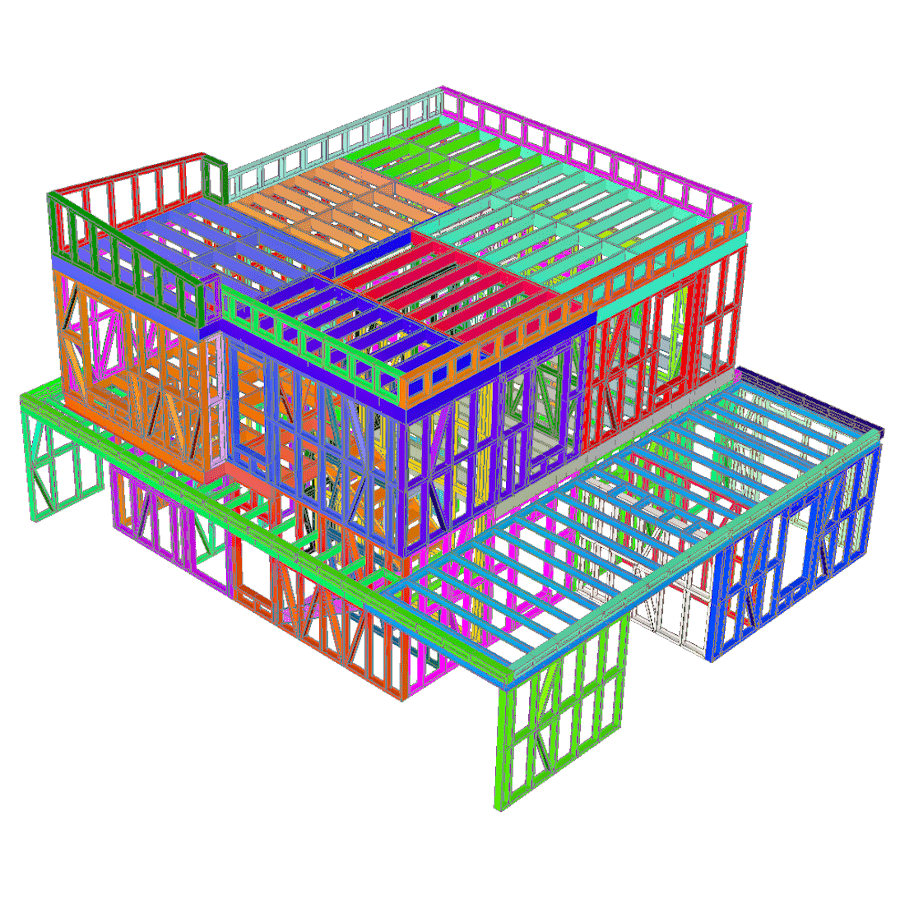

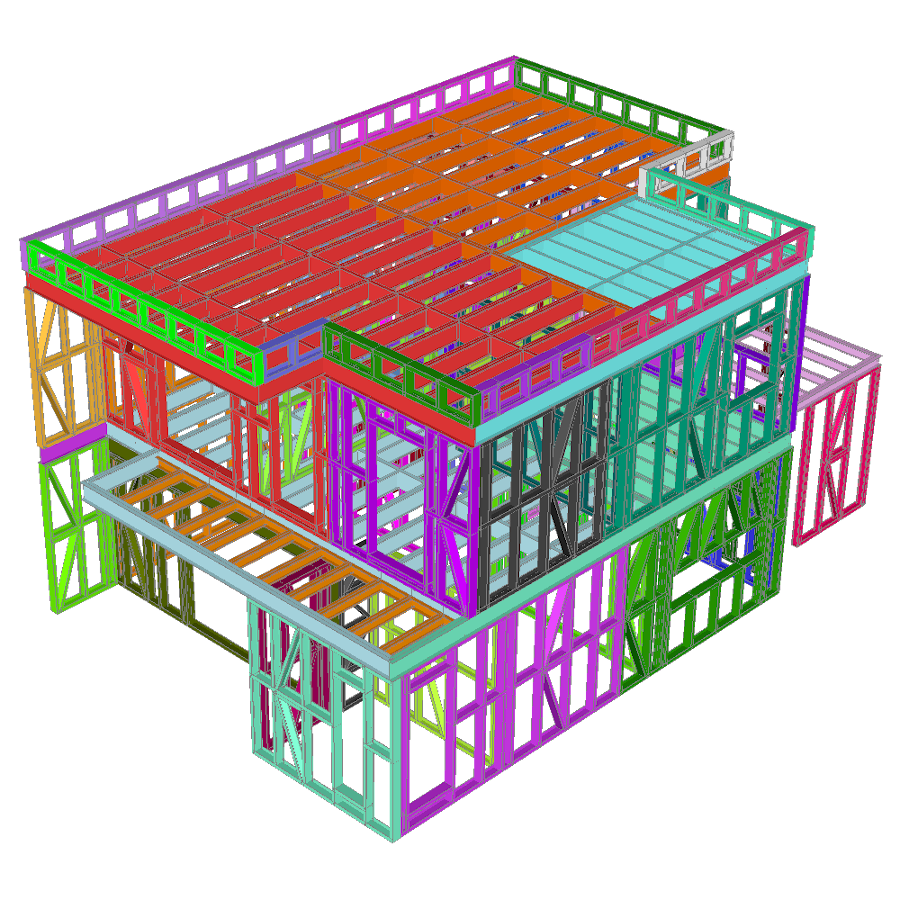

The Frame structure (LSF/LGS/LGSF) is entirely composed of cold-formed thin-walled steel profiles with zinc coating. These profiles are calculated and arranged to support the weight of the building, effectively and safely respond to various loads, and ensure its strength and stability throughout its service life.

MATERIAL PROPERTIES

Steel is a material with elastic behavior.

This property of steel is directly related to the thickness of the material and the dimensions of the respective profile.

At the same dimensions, as the material thickness decreases, the profile becomes highly elastic, whereas if the material thickness increases, its elasticity decreases. Controlled elasticity allows these elements to better withstand various stresses without allowing the appearance of cracks or compromising the profiles or the structure.

Steel has a very important property – slow yielding.

Frame structures made of cold-formed thin-walled zinc-coated steel profiles, in accordance with standards, perform very well during earthquakes due to their lightweight, controlled elasticity of the profiles, and the fact that the profiles that make up the structure withstand the applied loads very well.

An important advantage of frame constructions is that they exhibit excellent behavior during earthquakes and in case of building collapse.

The slow yielding phenomenon prevents the fracturing of the structural profiles, as they undergo torsion, bending, crushing, or tearing, but still leave enough space beneath the compromised elements, increasing the chances of survival for individuals under them compared to other types of constructions..

ARRANGEMENT OF LOAD-BEARING ELEMENTS

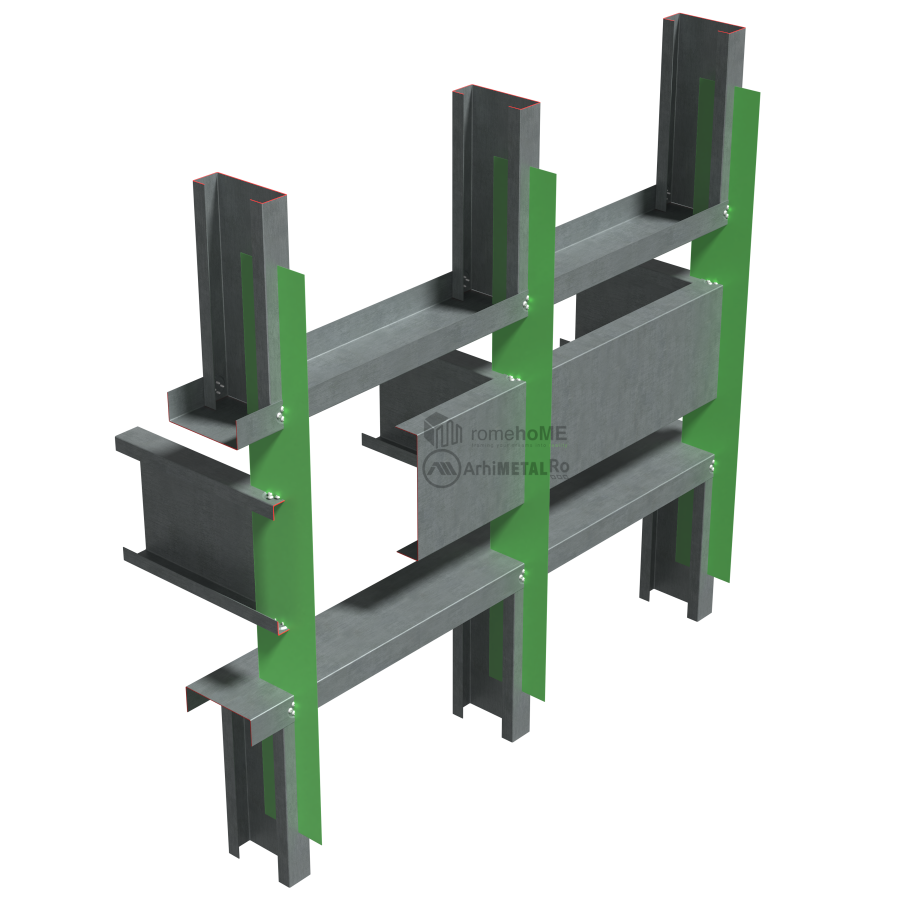

In the case of a frame structure made of cold-formed thin-walled zinc-coated steel profiles, the load-bearing elements (studs and beams) are made of ‘C’ profiles, while the ‘U’ profiles serve as guides and stiffeners.

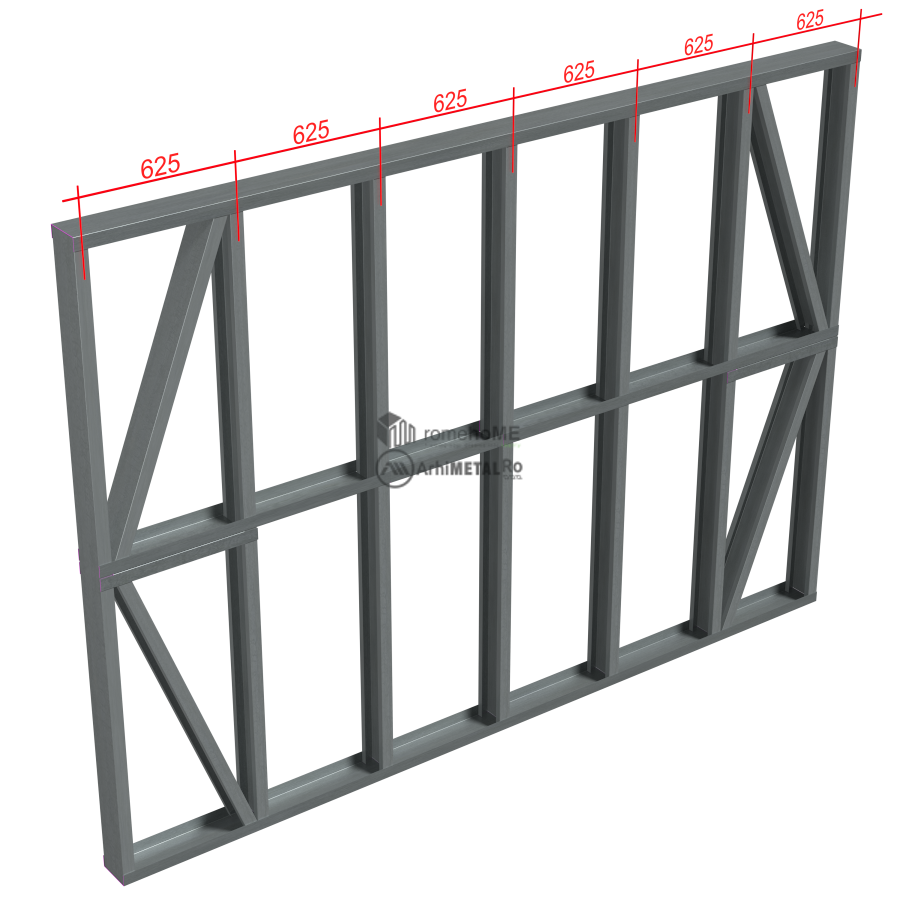

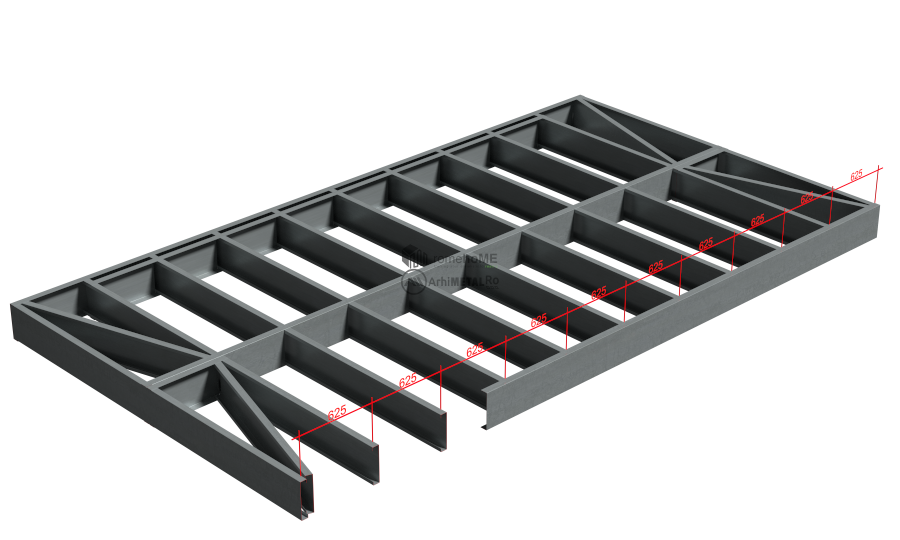

For all structural elements (walls, floors, roofs, etc.), the studs and beams are made of a single ‘C’ profile placed at a maximum distance of 625 mm from each other (on center).

Depending on the loads, span lengths, and project requirements, the studs or beams can be spaced closer together or doubled.

Another crucial aspect is the overlapping of the load-bearing elements.

As a general rule, this means that on the same centerline, the studs of the upper floor should overlap the beams of the floor, which, in turn, should overlap the studs of the ground floor. Minor deviations from vertical overlap are allowed, and the orientation of the profiles can vary from one structural module to another.

In the case of walls with openings for windows or doors, the arrangement of the studs may deviate from the rule, but the positioning is resolved by the structural engineer through 3D structural modeling.

RIGIDIZATION OF THE FRAME STRUCTURE

One of the important requirements that the frame structure must meet is that, although the base material is relatively elastic, it should exhibit a rigid behavior regardless of the applied loads (wind, earthquake, snow, equipment loads, furniture, etc.).

A rigid behavior means that the structure is strong and stable enough to support the specified finishes and equipment in the project (OSB or cement-based cladding, facade thermal insulation systems, interior and/or exterior finishes, equipment and installations, windows, etc.) without the risk of detachment due to induced vibrations or uncontrolled elasticity of the structural elements, thereby endangering the safety of occupants/users.

The frame structure needs to be rigidized before installing any type of cladding.

SHEET THICKNESS AND PROFILE DIMENSIONS

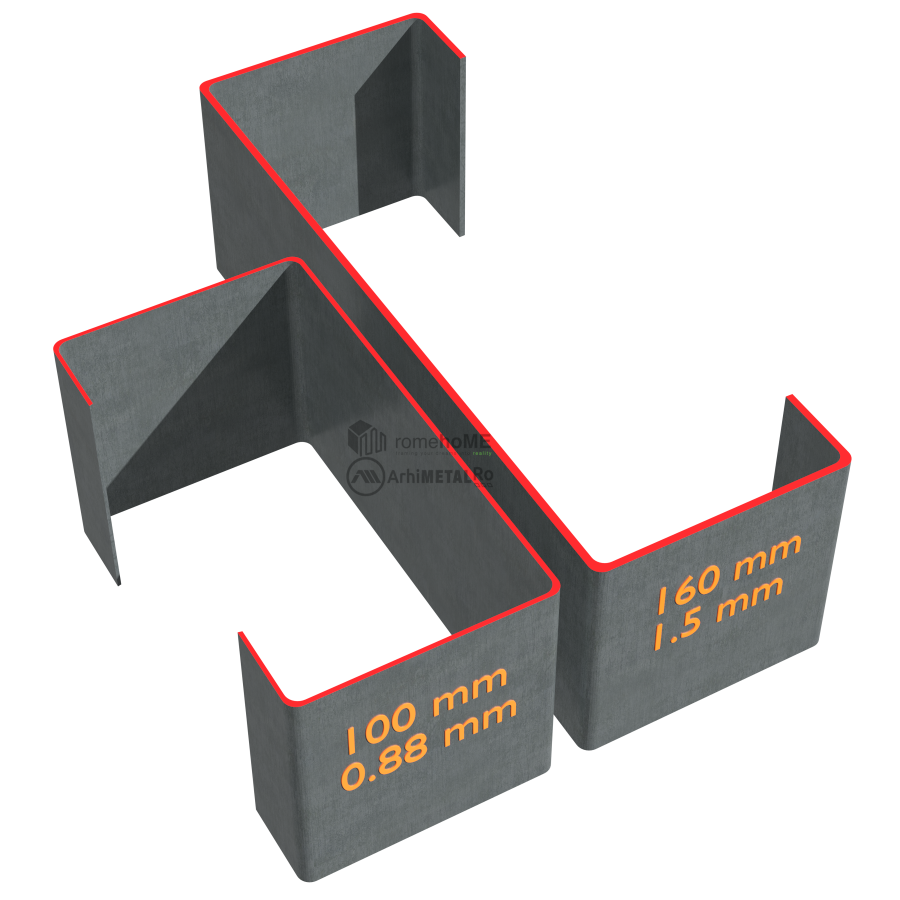

We consider a sheet thickness of 1.5 mm to be an optimal choice to ensure sufficient rigidity of the structure. The thicker the sheet used to form the profiles, the greater their rigidity becomes. There is a direct relationship between the dimensions of the profiles and the sheet thickness, aiming to achieve the best balance between the rigidity of the structural elements and the material consumption.

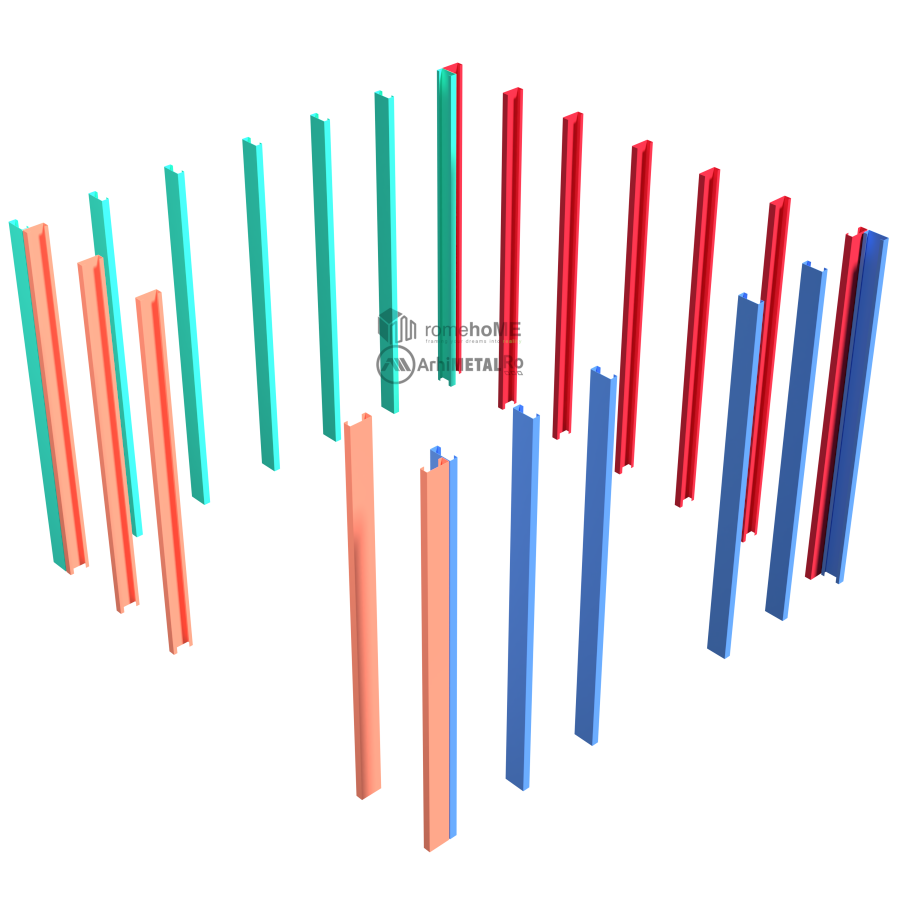

Two profiles with different thicknesses and dimensions are shown; the one made from a thinner sheet – left (0.88 mm) – is much more elastic than the one made from a thicker sheet – right (1.5 mm). All dimensional values influence the construction’s composition and behavior in order to meet the same requirements.

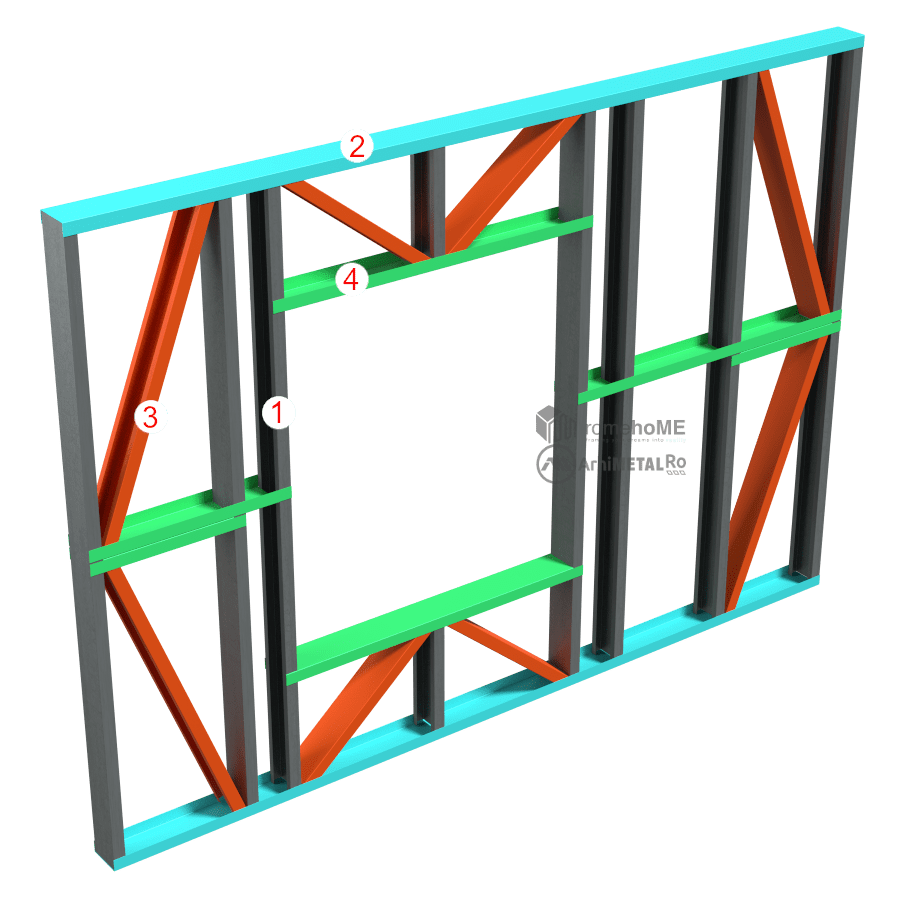

RIGIDIZATIONS AND BRACING

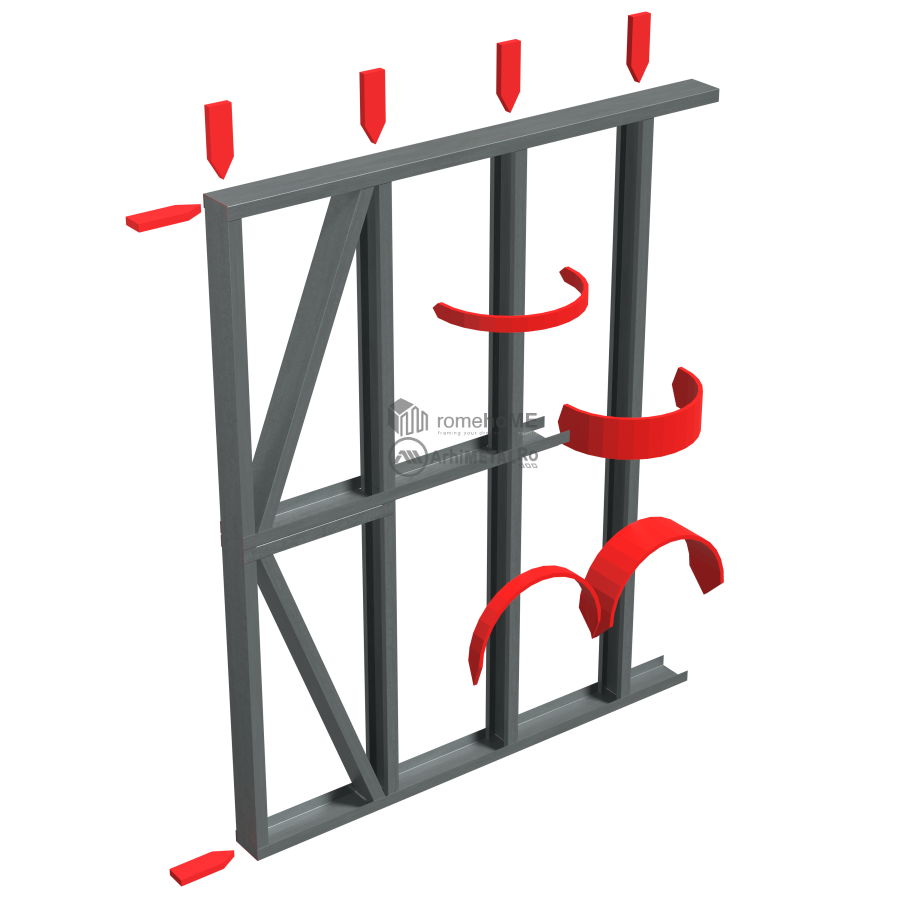

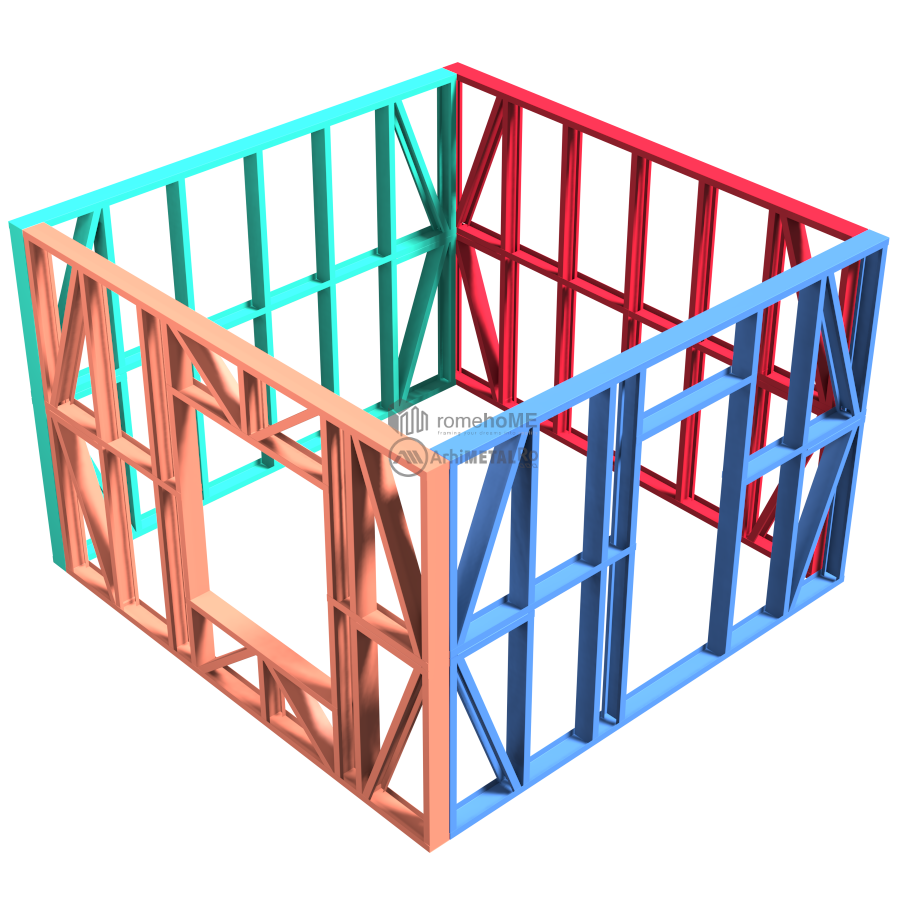

Rigidizations are made using U-profiles, which have the role of ‘shortening’ the length of the load-bearing element, the studs, and thus increasing the overall rigidity. The smaller the distance between nodes, the more rigid the assembly becomes. The arrangement of rigidizations is determined through structural calculations to avoid excessive material consumption. Equally important is the installation of braces/tie rods in the terminal areas of the modules to ensure increased rigidity in the joint areas with other modules (LSF)

It is considered that for a structural wall with a maximum height of 3.5 m, a medium-level rigidization (green) is necessary. If the rigidization were not installed, the length of the profile (L) in relation to its dimensions (width and thickness) could allow for the induction of vibrations in the studs and, consequently, in the wall.

In the case where the rigidization is installed, it can be observed that the length of the profile is halved (L/2), which, in relation to the same dimensions of the stud (width and thickness), reduces the possibilities of movement/vibration of the studs and increases the rigidity of the resulting elements. For taller walls, two or more rigidizations can be arranged.

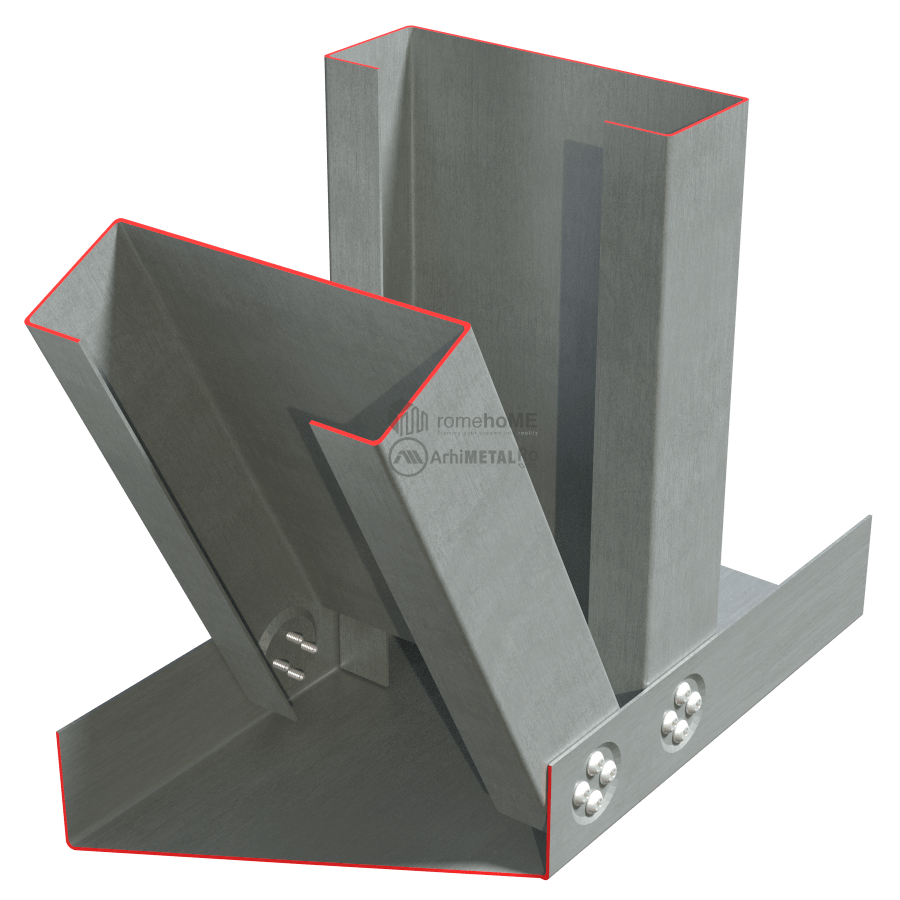

8 SCREWS/JOINT

The rigidization of the assembly joints between the ‘C’ and ‘U’ profiles is one of the important conditions that also affects the overall rigidity of the assembly. As we mentioned before, romehoME is the only company in the Romanian market that has the necessary technology to install 8 screws/joint, which contributes to the rigidity of the frame structure.

Ensuring the rigidity of the construction is one of the most important aspects for us as implementers of solutions when it comes to building a high-performance structure using the frame system (LSF).

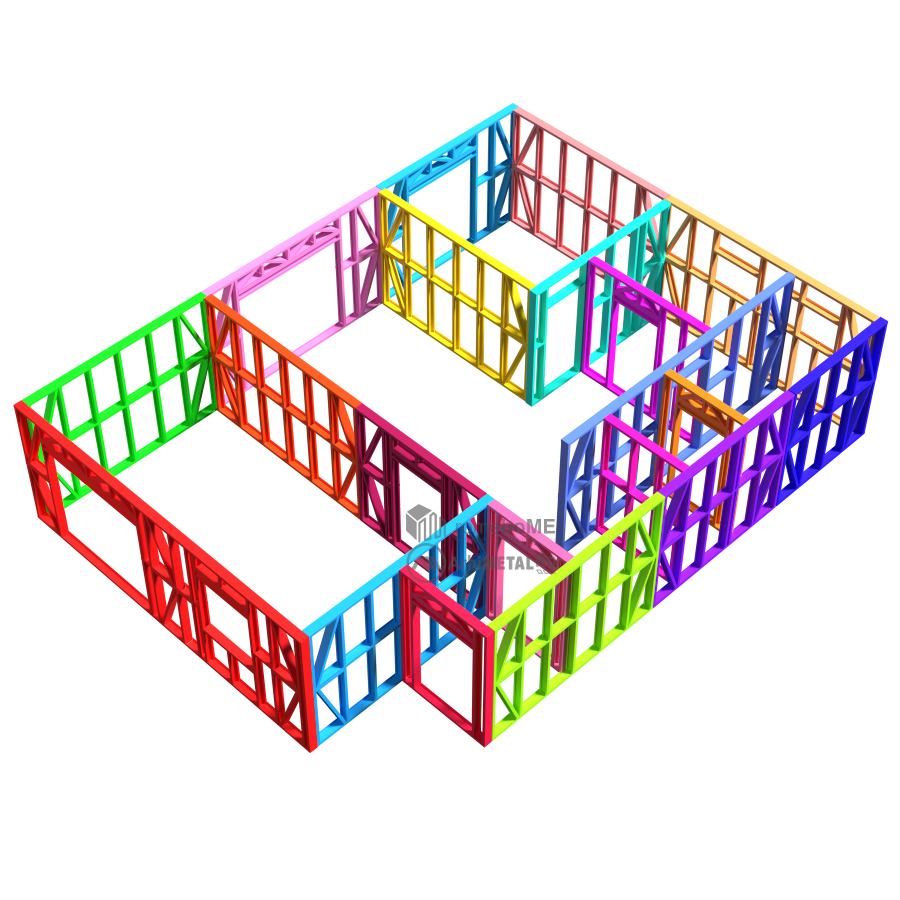

FUNCTIONING OF THE FRAME STRUCTURE - PRINCIPLE OF BUNDLE

From the elements mentioned above, it follows that the correct and safe functioning of a frame structure (LSF) is ensured by the large number of studs, their arrangement and configuration, the connections between them, the rigidity of the structural elements, and the fastenings/joints, acting on the principle of the bundle:

a single element may have low resistance to loads and actions, but when multiple elements are brought together, they act as a whole, withstanding various types of stresses very effectively.

This results in a unified structure where all the construction elements are made from the same material, very lightweight, strong, and stable, capable of meeting numerous requirements related to insulation, finishing, energy efficiency, etc.

The advantages of the frame structure support and enhance the benefits of houses and frame constructions in general.