The content of the site is protected by copyright as intellectual property. Without the written consent of romehome.ro, copying (in any form) of any part of the website (design, text, images, etc.) is not accepted.

„A lot of times, people don't know what they want until you show it to them” - Steve Jobs

Frame advantages

FRAME CONSTRUCTIONS

Reduced execution time

- construction of a house P+1 of 150 mp – between 3-6 months;

- dry construction methods are used(80-95%);

- wet construction methods with short usage times are used (20-5%);

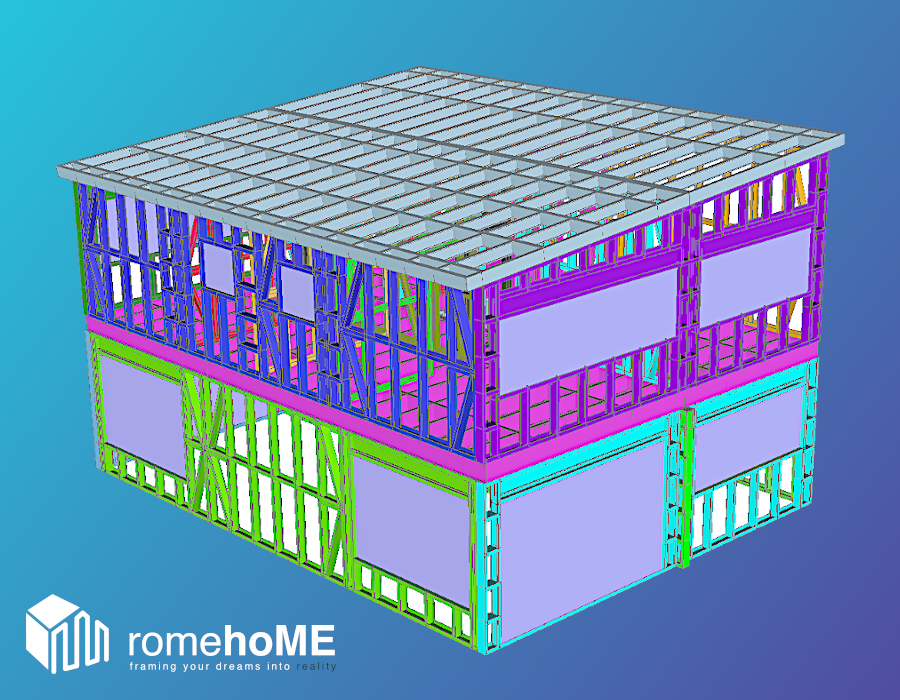

FRAME STRUCTURE

Fast production and installation

- the production of the frame structure is fast – 10 -12 hours for a house of 150 mp;

- assembly of the frame structure for a house of 150 mp with ground floor and first floor – between 6 – 12 days;

- It can be preassembled in the factory or on-site;

FRAME CONSTRUCTIONS

Easy implementation on any terrain

- foundations up to 40% reduced than a traditional construction;

- lightweight foundations on drilling piles can be used;

- lightweight materials are used in construction;

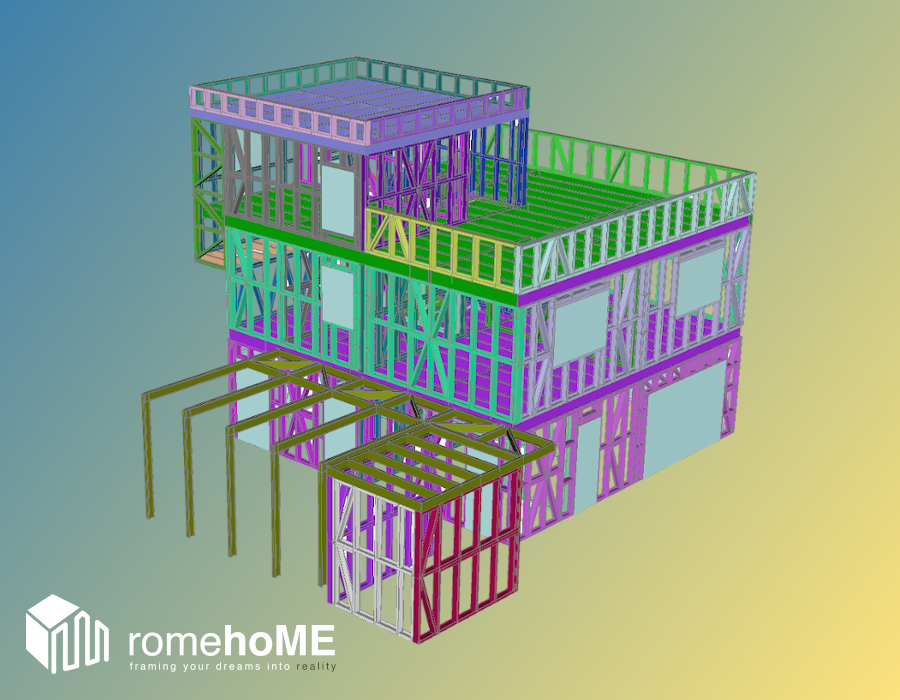

FRAME STRUCTURE

Reduced weight

- the frame structure weighs between 40 – 60 of kg/mp based on conformity;

- both the profiles and assembled modules can be easily handled;

- both assembled modules and profiles are easily transported;

FRAME CONSTRUCTIONS

Strong and stable

- very good behavior in case of an earthquake;

- it is not affected by wind, storms, snowfall, or pests;

- limits the occurrence of cracks and fractures in the structural elements;

FRAME STRUCTURE

Unified structure, rigid behavior

- we only use structural-grade steel;

- we use profiles with thickness of 1,5 mm;

- Structural stiffening – 8 screws/precast node;

- securing the modules with galvanized steel metric screws, group 8,8 with washer and nut;

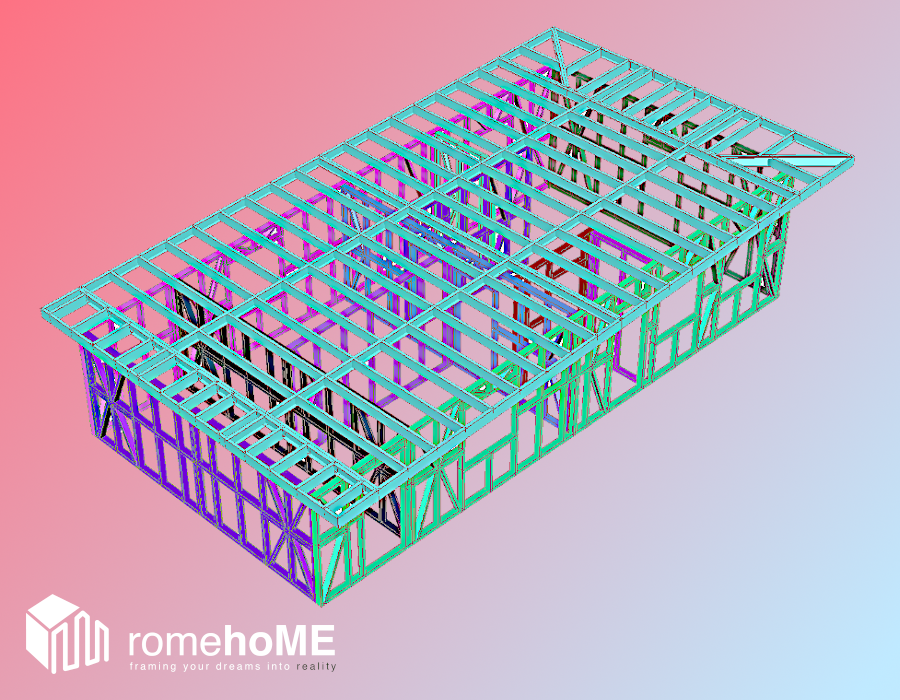

FRAME STRUCTURE

Precision and tolerances in mm

- the processing of steel sheet is done on high-precision, advanced machinery;

- 3D modeling of structures using dedicated calculation software;

- pre-bending and pre-drilling of profiles during manufacturing;

- assembly tolerances in millimeters;

FRAME CONSTRUCTIONS

Controlled and optimized consumption

- facilitates proper integration of structural and non-structural elements;

- reduces material losses and waste quantities;

- consumption and costs become predictable;

FRAME STRUCTURE

Protected against moisture and corrosion

- 275 g Zn/mp – the amount of zinc that ensures optimal protection;

- high-quality galvanized steel table from reputable manufacturers;

- the manufacturing process does not affect the zinc protection – anti-corrosion protection on the edges;

- frame structure lifespan is between 50 -250 years depending on the exposure of the profiles;

FRAME CONSTRUCTIONS

Healthy living space

- energy recovery ventilation systems;

- allows efficient control of temperature and humidity;

- stops the spread of dust, micro-particles, and volatile organic compounds (VOCs);

- improves the quality of the breathed air;

- prevents condensation and mold growth;

FRAME CONSTRUCTIONS

Environmentally friendly

- by using modern technologies, the environmental impact is reduced;

- the quantities of construction waste are greatly reduced;

- 80% of the materials used are recyclable;

FRAME STRUCTURE

Recyclable

- frame structure made of galvanized steel profiles is fully recyclable;

- raw material consists of approximately 60% recycled components;

- production process is carried out without any waste or losses;

FRAME CONSTRUCTIONS

The best option for energy-efficient constructions

- very low energy consumption in operation;

- indoor microclimate can adapt to a wide range of requirements;

- Versatile compliance, easily incorporating Smart systems;

FRAME STRUCTURE

The best option for energy-efficient constructions

- frame structure can support any energy efficiency concept: NZEB, PASSIV HAUS, MULTICONFORT, etc;

- thermal bridging can be prevented starting from the design phase;

- Multiple types of thermal insulation can be used;