Applying the principles in the design rules for cold-formed thin-walled sections requires running a static calculation on a structural model.

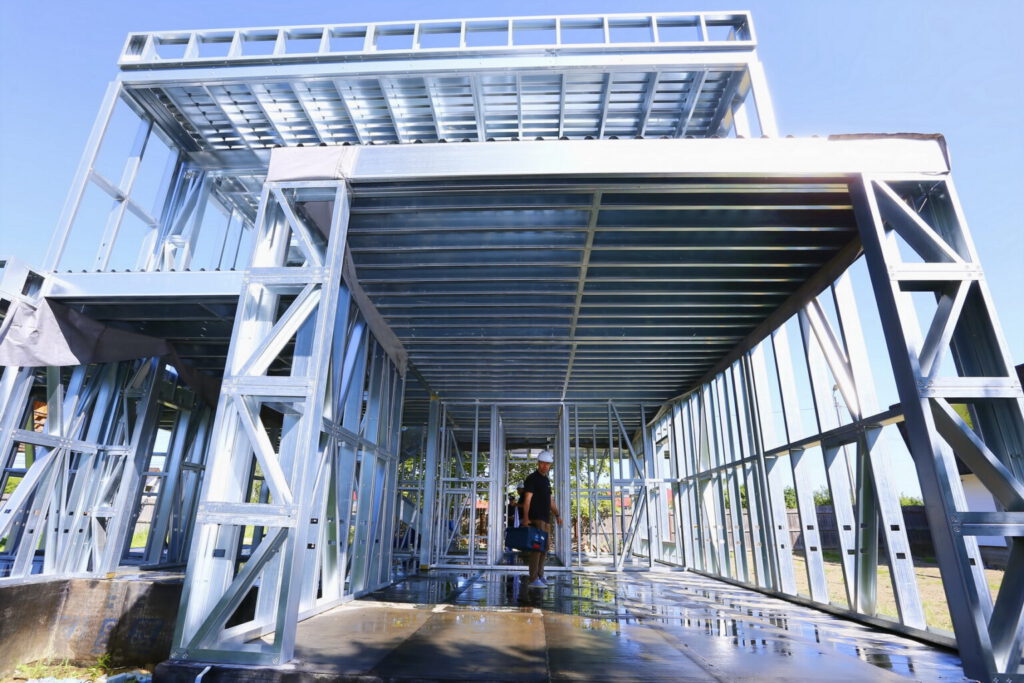

Due to the large number and density of component elements, the modeling, analysis and calculation of metal house structures as a whole remains a complex problem, due to the phenomena deriving from the thinness of the walls of the sections that these structures are composed of.

The local instabilities of the profile walls (local warping or distortion of the section) through the interaction with the loss of the general stability of the structural element, which may have local cutouts, or may be perforated for reasons of energy efficiency, generate situations that complicate the analysis of the behavior of the structures at the global level, but also at the constituent element level, for which instability is the main dimensioning criterion.

If to all this we add the geometric imperfections (geometrical deviations on the section and on the length), of the material (the influence of the manufacturing process on the mechanical characteristics of the steel, affected by ecruing and specific residual stresses from the cold forming process) and those resulting from the scheme of loading (eccentricities resulting from specific joining technologies), the design and execution of these structures, compared to those from hot rolled profiles, becomes an almost impossible mission.

Without adequate analysis tools or calculation abacuses, which cover at least part of the issues listed above, the design process can be a barrier to promoting these structures in the market, where delivery and execution time play an important role in judging the competitiveness of the solutions , compared to classic home products.

Using prescriptive methods to configure the resistance structure

The prescriptive methods are based on the application of simplified calculation rules for the constituent structural elements, which would have the precise purpose of simplifying the complex process described previously.

The reference document includes tables with permissible loads by main types of elements (wall studs, main and secondary floor beams).

The C100 and C150 uprights with thicknesses of 1.00 -1.50-2.00 mm are grouped on level heights of 2.60-3.00-3.50 m.

The proposed tables are developed according to the static pendulum scheme, considering both soles (inside and outside) fixed – thereby accepting the idea of excluding the loss of lateral stability by bending along the weak axis of inertia.

The bearing capacities in the table provided are established for concentrated compressive loads applied centrally (eccentricity e=0) and loads applied eccentrically (e=h/12 and h/6), neglecting the effect of the bending moment from the action of the wind on the outer tire. In the case of the profiles used to make the floors, 3 types are available to configure the solution: C, Σ, 2U compound resulting in an I section.

The available size range is C150-C200-C250, Σ 200-Σ 250 and I150-I200- I250 with thicknesses of 1.00-1.50-2.00 mm and provide the user with the permitted opening depending on the payload (q= 2.00 and 2.50 kN/m2) and the center distance of the beams (b=400 and 600 mm).

The bearing capacities in the table provided are established for the bending resistance in the field and the shearing force resistance on the support, considering both footings (lower and upper) fixed.

Similar but much more thorough details (including implementation details) can be obtained from [3].

Following these directions, we can configure houses on metal structure from light profiles with the solutions covered in the details provided.

Subsequent additions to [3] by chapters, address materials, particular structural elements and design methodologies.

It is certain that prescriptive methods do not cover structural configurations of any shape. In these situations, the design engineer must resort to a detailed calculation.

Authors of the document

Zsolt Nagy – Lecturer, Cluj Technical University, Faculty of Construction, Department of Structures

Cristina Câmpian – Professor, Cluj Technical University, Faculty of Construction, Department of Structures

Paul Perneș – Assistant, Cluj Technical University, Faculty of Construction, Department of Structures