Metal houses on a light metal structure can be designed in such a way as to result in very low energy consumption, even in very cold climates.

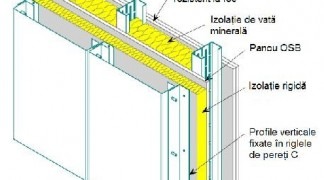

By using perforated profiles with increased energy efficiency (Figure 1) and adequate insulation, houses can be obtained, whose energy consumption should fall below 50% compared to the energy requirement of conventional buildings.

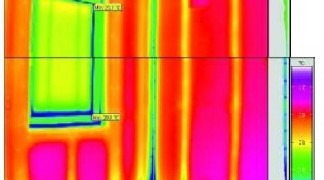

In the wall structure by simply replacing solid C200 profiles with perforated C200 profiles, the U coefficient of heat transfer of the wall, without considering the outer layer of rigid thermal insulation, changed considerably from values above 0.35 W/m2K in the case of C profiles full at values below 0.20 W/m2K in the case of perforated C profiles.

The efficiency of the walls by using perforated profiles can reach performances similar to those of the walls of wooden structures.

Variants of solutions are studied and presented in [16], some solutions ensuring a heat transfer coefficient of 0.19 W/m2K.

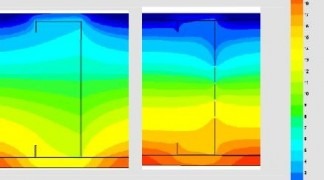

Figure 2 – Wall solution (a) and C-profiles and perforated C-profiles in thermal analysis (b) [15].

Figure 3 – Infrared photo of a wall corner made with light profiles [16].

Perforated profiles, effective from the thermal and acoustic point of view, suffer resistance degradation, precisely due to the perforations.

Finding the ideal perforations, which ensure high energy performances, but at the same time a satisfactory behavior from the point of view of resistance, is an open topic, researched at the moment as part of the doctoral theses in progress at the Technical University of Cluj.

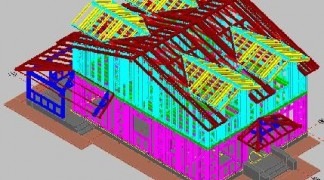

Even if perforated profiles are not used, by adopting appropriate insulation solutions, excellent energy performances can be obtained. The house in Câmpinița Street – Bucharest (Figure 4) was made in 2012 from non-perforated C150 profiles.

The wall insulation was made with the following layers: 2×100 mm Rockwool Rockmin Plus mineral wool mattresses placed between the wall C profiles, Widiwall plates and external thermosystem with 100 mm insulation from Rockwool Frontrock Max mattresses.

The roof insulation was made with 2×100 mm Rockwool Rockmin Plus mineral wool mattresses placed between the roof C-profiles, 15 mm OSB placed on the outside and an additional 100 mm Rockwool Rockmin Plus insulation under the resistance C-profiles, in a grid of Rigips profiles to lower the ceiling by 100 mm.

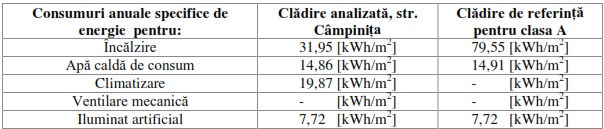

Following the calculations carried out to obtain the energy performance certificate for an area of 208.29 m2 and a heated volume of 656.72 m3, a specific annual energy consumption of 54.54 kWh/m2 year compared to 102.19 kWh/m2 year resulted of a reference building, placing the building in energy efficiency class A, which confirms the previously stated percentage of 50% energy consumption compared to the energy requirement of a conventional building.

The CO2-equivalent emission index according to the energy certificate results in 13.46 kg CO2 /m2an, compared to 23.23 kg CO2 /m2an of the reference building for class A from the point of view of energy efficiency.

In conclusion, we can declare that the myth of the “cold” sensation is dispelled, houses on a light metal structure with adequate insulation solutions prove their energy efficiency.

Figure 4 – Dumitrache House from Câmpinița Street – Bucharest, made with light profiles

Table 1 – Annual specific energy consumption, Casa Dumitrache – Bucharest

Authors of the document

Zsolt Nagy – Lecturer, Cluj Technical University, Faculty of Construction, Department of Structures

Cristina Câmpian – Professor, Cluj Technical University, Faculty of Construction, Department of Structures

Paul Perneș – Assistant, Cluj Technical University, Faculty of Construction, Department of Structures