Myths and truths about houses with light metal structure

For many house-seekers we have launched the question: In which house would they like to live their life and why? A conventional brick one or in a metal house?

The answers were very varied, in many situations the choice was influenced by myths, which took root in the consciousness of ordinary people, having no real scientific support.

We analyze some of these myths and truths and formulate answers based on scientific engineering methods to quantify the answer.

The article addresses the subject of energy efficiency and resistance design of houses on a light metal structure and highlights answers to the problems analyzed through the prism of some examples of designed and executed houses, used as a case study.

To what extent these answers will change the opinions of home buyers over time, it remains for each individual to decide their choice.

We hope that the information collected in this paper will be of help to you.

Compared to the beginning of the 2000s, when the idea of houses on a light metal structure was launched on the residential market in Romania, potential users looked with great skepticism at the technical solutions, which had been practiced for a long time in the North American, North-West European market (Scandinavian countries , Great Britain), Australian-New Zealand, Japanese.

The global financial crisis of 2008 also strongly affected the residential market in Romania, but it seems that many turned to the solutions of metal houses made of light profiles, registering a constant growth of the market in this segment.

At the moment in 2015 we see a wide penetration of the Romanian residential construction market with many execution companies and real estate investors on metal house solutions.

One of the initial barriers in the promotion of light metal house solutions on the Romanian market was related to the idea of the incompatibility of class 4 structures of sections (considered as structures with reduced ductility) and the high seismic risk of the area, a myth dispelled after the performance evaluation of these types of structures to seismic actions in areas with high seismicity, having ground acceleration of 0.2g.

The use of cold-formed thin-walled profiles of C, Σ, U, Z sections in the case of these structures and the continuous development of high-strength steels, involves solving special design problems, which are not encountered in the design of structures made of steel profiles ordinary, obtained by hot rolling or by welding sheets.

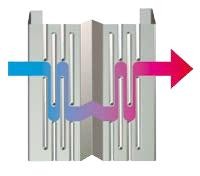

The difficulties in the design of these structures become even more accentuated, by providing slots on the heart of sections C, Σ, U, Z, in order to increase the thermal and acoustic efficiency of these profiles (Figure 1).

That’s why the overall concept of house structures made of cold-formed thin-walled steel profiles, the composition of structural elements, with simple or compound sections, the methodology and details of joining, their design, are different from classic metal structures.

Consequently, specific calculation and design norms were developed for these structures.

In order to simplify the designers’ task, these types of structures have acquired prescriptive design forms in the North American market, where profile typologies and constructive solutions can be selected according to geometric dimensions, openings, heights.

Later, separate volumes were published, in order to cover the issue of design by subject chapters [4…13].

A similar attempt was made for the European Union market, initiated by the LSK association (Europe an Lightweight Steel-framed Construction Association), materialized in the end by a low-impact publication, produced by Arcelor.

Figure 1 – Thermally and acoustically efficient profiles (source www.lindab.com)

The prescriptive methods are based on the application of simplified calculation rules for the constituent structural elements.

Due to the high number and density of component elements, the modeling, analysis and calculation of metal house structures as a whole still remains a complex problem, which acts as a barrier in promoting solutions on the market.

The constructive closing solutions based on dry technologies, which have undoubted advantages in terms of energy and the speed of execution of these types of houses, have a different operational behavior compared to the classic solutions that users are used to, if we refer to plastered brick buildings .

Dry technologies, whose walls become impermeable, ensure good thermal insulation and a different microclimate compared to classic brick solutions, which are permeable (masonry + plaster), requiring the provision of a mechanical ventilation system.

Constructive solutions for horizontal space separation (intermediate floors) based on dry technologies require careful treatment of the problems related to sound insulation and vibrations in their operation.

In the following, some of the aspects mentioned above will be discussed based on case studies and normative reference documents, which regulate the design of these types of structures.

The project was completed in 7 days and the construction of the structure itself took about 10 days.

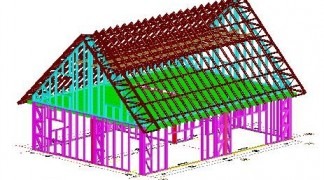

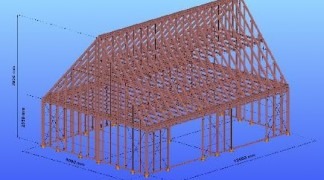

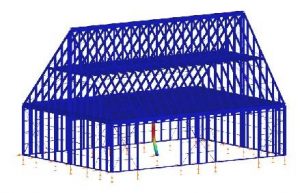

Figure 5 – Structural calculation model vs. the project made with light profiles

The 3D calculation model of the structure was made in the Consteel analysis and structural calculation program, considering simplified 3 pendulum stabilization links on the height of the wall uprights, intended to model the effect of the external and internal borders.

The floor beams were modeled in the same way, considering 3 stabilizing pendulum connections per opening.

The roof beams as rafters were provided between the supports secured by the links provided with one pendulum stabilization link each.

The corners of the structure, both in the wall and in the roof, were braced with steel strips, being defined as elements that can only take tension.

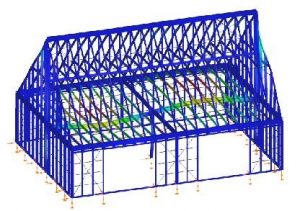

Although the number of links in such a structure in reality is much higher, the structural assembly in Figure 5 presented a very good response to the global stability analysis: the first element that loses its stability in the structure is the central pillar made of laminated profile HEA140, the critical load multiplication factor from the dangerous combination (permanent loads+useful floor) resulting being αcr=6.86 (Figure 6a).

The buckling sensitivity analysis highlights the elements sensitive to the loss of global stability those with fewer connections (the rafters, which were very rarely fixed).

The results of the global checks, according to the Eurocode calculation methodology, indicated a degree of use of the elements of a maximum of 88%, these being generally the edging profiles of the gaps, which accumulated a higher load due to the lack of uprights on the surface of the gaps.

a) αcr=6.86 b). Tfloor=4.66 Hz

Figure 6: The result of the stability analysis and that of the dynamic analysis

It is interesting to note that the strength checks indicate that C150x2.5 profiles are also suitable for the floor beams, but in the dynamic analysis vertical vibration appears at a frequency below 5 Hz (Figure 6b), which can generate undesirable effects in operation in the combination loads 1.35 x permanent + 1.5 x useful.

The results of the dynamic analysis using C200x2.5 profiles show that the same vibration form occurs at a frequency of 5.56 Hz, which is still very close to the recommended critical threshold of 5 Hz.

Figure 7: The structure of the analyzed house in the execution stage

Authors of the document

Zsolt Nagy – Lecturer, Cluj Technical University, Faculty of Construction, Department of Structures

Cristina Câmpian – Professor, Cluj Technical University, Faculty of Construction, Department of Structures

Paul Perneș – Assistant, Cluj Technical University, Faculty of Construction, Department of Structures