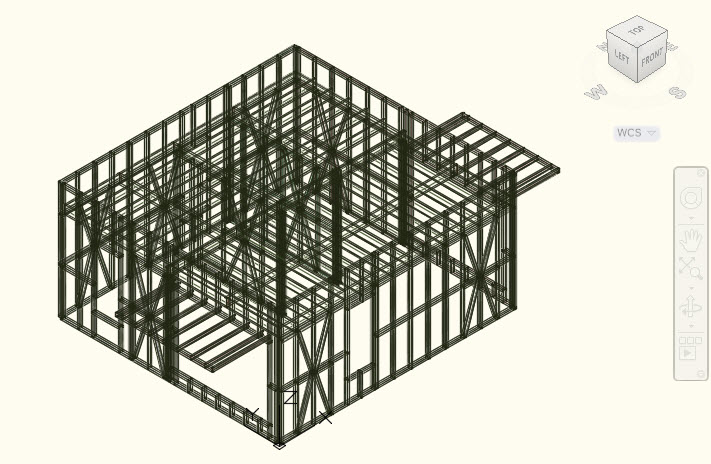

Production line of prefabricated flexible C and U profiles for walls, trusses, ceilings and floors.

Walls, fixing frames and floors for prefabricated buildings such as: houses and villas, office buildings, social spaces, modular containers, facade elements, etc.

The profiles are produced with all the necessary perforations (according to the worksheet) such as joint details, screw holes, through holes, openings, …

The advantages of prefabricated metal structures made of galvanized sheet profiles

The best structural solution with the best price-quality ratio

Most cost effective midrise structural material

…

Shorter and predictable construction schedule

…

Highest strength to weight ratio of any building material

…

100% recyclable

…

68% industry recycling rate

…

Noncombustible, does not burn nor contribute fuel to the spread of a fire

…

Inorganic, will not rot, warp, split, crack or creep

…

Dimensionally stable, does not expand or contract with moisture content

…

Source: (Mazzolani si Piluso, 1996)

Saves job site time with ease of penalisation off site

…

Lighter than other framing materials

…

Straight walls and square corners

High strength results in safer structures, less maintenance

…

Fire safety, doesn’t burn or add fuel to the spread of a house fire

…

Less probability of damage in an earthquake

…

Lighter structure with stronger connections results in less seismic force

…

Less probability of damage in high winds

…

Stronger connections, screwed versus nailed

…

Source: (Mazzolani si Piluso, 1996)

…

Using mixed solutions of prefabricated facade walls, partitioning solutions or prefabricated toilet solutions, containing profiles with thin walls, cold rolled, in multi-storey buildings, we benefit from a predictable planning, which can reduce the delivery terms of a building by several months .

It also has a more predictable schedule/planning, which can significantly shave months off the total project cycle time.